Project Description

DIN67520 Reflective Barrier Facing Stripe

Reflective Barricade Tape is impact resistant and exceeds ASTM D4956 specifications for Type I and Type III and EN12899 RA1 and RA2. The reflective tape is designed for hazard warning barriers, road-end reflective barricades, and any equipment requiring a high visibility warning and conspicuity. Reflective Barricade Tape usually have 3 kind of colours – white / red, yellow / black, yellow / red.

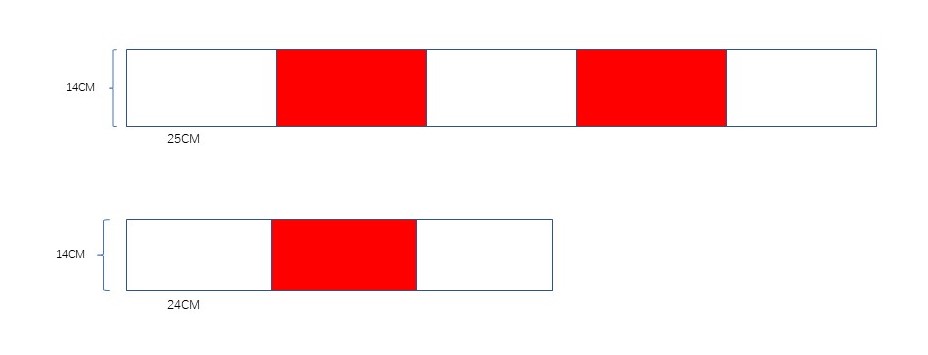

The popular size for pre-print reflective barricade strip are 0.14m*1.25m(space 25cm)and 0.14m*0.72m(space 24cm), these reflective tapes are suitable for barricade boards and guiding elments in European.

Solutions

RA1 pre-print reflective strips

Engineer grade reflective sheeting XW7200 meets the EN12899 RA1 and ASTM D4956 Type I standards, which is a medium-intensity retroreflective material and typically enclosed lens glass-bead sheeting. Typcial applications for this reflective material are permanent highway signing, construction zone devices , and delineators.

RA2 pre-print reflective strips

High intensity grade reflective vinyl XW1800 certified by EN12899 RA2 and ASTM D4956 Type III standards, which is a high- intensity retroreflective vinyl and typically encapuslated glass-beaded retroreflective material. The typical application is permanent highway signing, construction zone devices and delineators.

Reflective Sheeting Prodution

XW Reflective manufacturer is a leading reflective material supplier, reflective tape sheeting factory, mainly provide & manufacture top quality reflective fabric for knids of reflective material distributor all over the world. Whether quality control or reflective sheet production time, XW Reflective always do it best, serve every refelctive self adhesive vinyl customers well according to their requirements.

Reflective sheeting is one of reflective product of XW Reflective, made by PVC / acrylic / PET or mix face film, our reflective material customers can choose the suitable reflective vinyl according to their product, reflective pvc films are good for digital print, reflective acrylic film is sutiable for screen print, PET reflective film can accpect plotter cutting, and all of them can be used to do UV printing.

Of course, if you have strict requirement about reflection value, we also provide different reflective sheeting with kinds of reflective value.

Leading Time of Reflective Sheeting

- We have regular stock of reflective sheeting products for sale in the warehouse, if not, it will take 7-10 days to arrange reflective sheeting production & shipment after deposits receive. Thus, please confirm with XW Reflective maufacturer before ordering our reflective tape material.

OEM & ODM

- Customized reflective sheeting width available( Can’t over the Maximum width).

- Customized reflective vinyl sheeting package mark service.

- For any client’s who want printing LOGO on retro refelctive fabric, please contact with our staff and it request a high quantity.

- For order less than 100 rolls, we can do OEM Carton and Product mark

- For order more than 100 rolls, and request your own logo, it needs one more deposit: USD 800 for cylinder cost

Quality Control for Reflective Sheeting

-

Raw reflective material inspection

XW Reflective has a strict quality control for reflective sheeting material production, from face film to release paper, all the maufcturing material of reflective taple vinyl will be strictly inspected before putting into production.

XW Reflective always check reflective manufacturing materials, and must ensure these raw reflective vinyl sheeting is in line with standard of reflective vinyl stickers production, then take away the disqualified raw reflective material, finally, XW Reflective will arrange reflective sheets manufacturing by the leftover reflective initial material.

-

Reflective material check during production

QC will cut production samples, bring it to our own lab then inspect brightness, stretch, thickness, etc.,also they will bring Brightness detector to production line and check for brightness.

XW Reflective arrange 3 technical staff to inspect reflective tape manufacturing in every reflective material production line, they can take measures quickly and adjust reflective sheets production once reflective pinstripe tape production occurs some quality problem, in addition, they will paste poor quality signs on these problem reflective products, deliver them to QC lab for a quality analysis.

-

Final inspection of reflective material

When Rolling the final product, workers will check and remove the poor quality sheeting and mark the joint. Each joint we arrange extra reflective sheeting for clients. If the joints out of allowable range, we label the roll as B grade.

We will sample test the final product, and also do inspection under client’s requested.

After Sales

XW Reflective try our best to reduce the quality problem for our reflective glow in the dark heat transfer vinyl, but if you still find quality problem in our heat reflective fabric, please don’t hesitate to contact us for best after sale service, and XW Reflective will provide best after service until you are satisfied with our service.

If you find your product has poor quality reflective material – whatever how many they are. Take a picture or video for it, show us, and our team will reply within 24 hours.