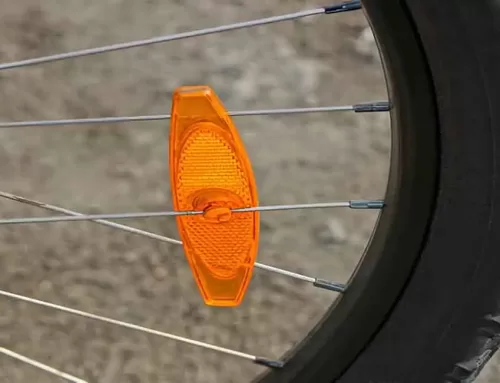

1. What is the reflective heat transfer film?

Reflective, retroreflective actually, is similar to the feature of glass bead coating on type reflective sheeting. Where the light comes; where the light goes. Therefore it looks bright and white with light during the night time.

The heat transfer means the application method is heat pressed or ironed on textile. The high temperature will melt the hot-melt adhesive on the back, then fix on textile with cooling off. There is the transparent PET liner on the reflective side for protection during handling.

And there will be extra PE liner on the adhesive side for BPU type. (*PES suitable for polyester or cotton material. BPU is much better in elasticity and could be used on stretchable material.)

2. How to use the heat transfer film in a proper way?

1) Cutting: Die-cutting is recommended, although it can also be hand-cut. For BPU, laser cutting is better and be sure to remove the extra plastic liner on the adhesive side before applying plotter cut and heat transfer.

2) Conditions: Temperature: 140-165℃; Time: 8-20 second; Force>0.5 kg/cm2

3) Heat Lamination: Work on a flat surface where heat and pressure can be applied. Do not heat over seams and stitches; Allow heat transfer film to cool to room temperature. Remove the reflective liner by lifting one corner and pulling (180°angle) in a continuous, smooth manner.

3. Any Care and Maintenance Instruction from XINGWEI Reflective?

Mainly for Washing Instruction: at first, should be in accordance with different washing standards accordingly. For details: DO NOT dry cleaning or bleaching. The heat transfer film is not suitable for printing.

4.Reflective Heat Transfer Film from XINGWEI Reflective

We have PES and BPU two kind material of heat transfer film, and the most popular colors are GRAY and SILVER with high reflection. Colorful choices available and we have also rainbow color film too. Three important factors of the performance as follows:

1) Reflection value: from 150 cd/lux/sq. to more than 420 cd/lux/sq. for silver and gray color

2) Washing instruction: 15 cycles and 25 cycles of home washing at 60℃ (ISO6330)

3) Certificate: ISO6330, EN20471-2013, ANSI/ISEA-107-2010, OEKO-TEX 100

Continuous testing should be done to ensure acceptable adhesion during mass production for heat transfer film. Feel free to contact us for any specific application assistance.

This web site is really a walk-through for all of the info you wanted about this and didn’t know who to ask. Glimpse here, and you’ll definitely discover it.