Photoluminescent Film Supplier – XW Reflective

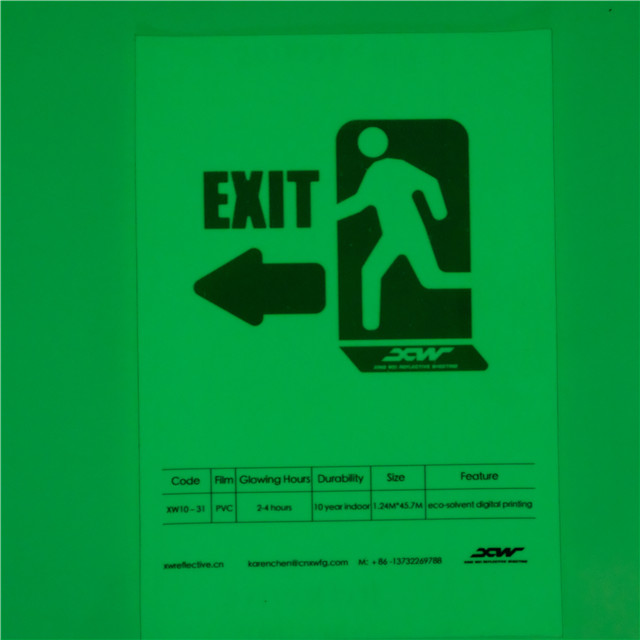

PVC Digital Printable Photoluminscent Film XW10-31

XW Reflective supply photoluminescent film digital Printable, the code is XW10-31, with self-adhesive vinyl, intended for use on emergency signage in buildings. The luminescent vinyl will absorb any light source, and it will glow during poor lights, the glowing duration is different, you can choose your suitable ones, or talk with our sales team.

PET Plotter Cutting Glow In Dark Tape XW10-11

luminescent tape is made of Photoluminescent pigment coating onto PET vinyl. The phosphor will absorb light radiation, then emit it back out, that's where glowing coming from. The glowing in the dark signs absorbs any lights in day time, including the light energy, the stronger light source, the more radiation will absorb. Therefore,the glowing signs will glow in night time or dark.

♦ Quick Purchase Guide Of Luminescent Vinyl Film

Luminescent film is applied for arrow signs, exit signs, decoration signs and emergency signs, etc, the face film includes PET, acrylic and PVC material, with different glowing hours for different face film, can be used to screen print, digital print, and plotter cut, you can choose the suitable one according to your application, and the following is the quick guide to you, all of these three luminescent vinyl films can be tailored in size.

| Code | XW10-11 | XW10-21 | XW10-31 |

|---|---|---|---|

| Face Film | PET | Acrylic | PVC |

| Durability | 10 years indoor 3 years outdoor |

10 years indoor 3 years outdoor |

10 years indoor 3 years outdoor |

| Size | 1.24M*45.7M | 1.24M*45.7M | 1.24M*45.7M |

| Glowing Hours | 2Hrs-4Hrs 4Hrs-6Hrs 6Hrs-8Hrs 8Hrs-10Hrs 10Hrs-12Hrs |

2Hrs-4Hrs 4Hrs-6Hrs 6Hrs-8Hrs 8Hrs-10Hrs 10Hrs-12Hrs |

2Hrs-4Hrs 4Hrs-6Hrs 6Hrs-8Hrs 8Hrs-10Hrs 10Hrs-12Hrs |

| Screen Print | N/A | √ | √ |

| Digital Print | N/A | N/A | √ |

| Plotter Cut | √ | √ | √ |

♦ Why Photoluminescent Film Can Glow

This luminescent film absorb ambient light, can be charged by any source of lights as long as strong than 25LX light intensity, such as a standard lamp, and this luminescent film can glow high-intensity initial lighting in range 2-10 hours’ time, then with the time goes by, this luminescent film slowly decreases lighting intensity after 2-10 hours. Of course, the specific high-intensity glowing time of photoluminescent film depends on different level of the luminescent film. So this luminescent vinyl film is a self power signs, because the film requires no extra illumination to glow. In daytime, the photoluminescent film show greenish colour, and it glows bright green in the dark.

♦ What XW Reflective Produce

XW Reflective produce both PET and PVC type luminescent vinyl film, PET type can be plotter cutting, and PVC matte surface is suitable for eco solvent digital printing. We supply different glowing hours, thus to meet markets and application needs. The most popular glowing duration hours are 4-6 glowing hours, 6-8 glowing hours. The durability is 10 years in door, 3-5 years outdoor.

♦ Photoluminescent Film Application

- Evaculation guidelines signs

- Fire extinguisher signs

- Budiling material signs,including handrails, stpes application

- Personal protect material, including bikes, helmets

- Toys and stationary

- Interior decors

♦Luminescent Vinyl Film Advantage

- Non-radioactive

- Non-toxic

- Meets Phtoluminescent Safety Productsa Assocation

- Easy to cut and operation

- Self adhesive with Permanent

Our photoluminescent film materials can be purchased from China directly or our distributor locally, With photoluminescent materials, any further inquiry, DROP US A MSG, we will reply you shortly.

CONTACT US

Please fill out my form, XW Reflective will contact you in 24 hours.

Photoluminiscent Film FAQ Guide

The photoluminescent film is a unique self-powered film that can absorb and emit light on its own. It is also called glow in dark film.

The photoluminescent film has a wide range of applications across different industries due to its amazing properties and tremendous advantages.

This guide presents you with detailed, valuable, and easy to understand information about photoluminescent films.

The photoluminescent film is a flexible luminous film that is used for exit signs, signposts, safety signs, fire safety signs, evacuation guideline signs, emergency signs, interior decors, etc. It is made up of PVC or PET layer and a glowing powder. The photoluminescent film has a unique ability to absorb ambient light and glows in darkness for about 12 hours. This is why it is also called glow in dark film.

- PVC Digital Printable Photolumiscent Film XW10-31

- PET Plot Cuting Glow in Dark Tape

- Plot Cutting Glow in Dark Tape

The photoluminescent film can glow because it is a photoluminescent material. Photoluminescent material is a material that emits or radiates light from its surface after absorbing light energy. The photoluminescent film absorbs ambient light during daytime and glows or shines in darkness by releasing its absorbed light energy.

The photoluminescent film can be charged by any source of light, provided the light intensity is greater than 25LX. Even a standard lamp can charge it. It glows with high light intensity in the first 2-10 hours but gradually reduces after that. The glowing intensity of a photoluminescent film is highest during its first 30 minutes of light emission.

All photoluminescent film products are self-powered. This means when a photoluminescent film product like a safety sign is charged by ambient light, it can emit light or glow on its own. It does not require any external light source or power to shine after it’s been charged.

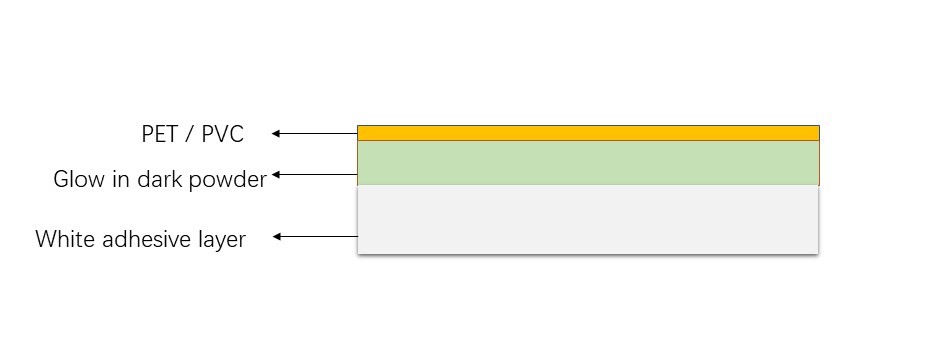

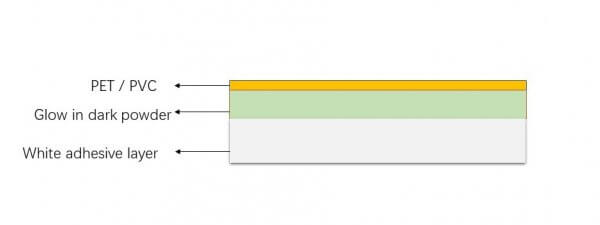

A photoluminescent film has three main components or layers. They are:

- PVC or PET face Film layer

- Glow in the dark powder

- White adhesive layer

Layers Photoluminescent Film

Yes, glow-in-dark films are durable.

Photoluminescent film’s durability is 10 years when used indoors and 3-5 years for outdoor applications.

As a leading photoluminescent film manufacturer in the world, XW Reflective supplies high-quality and durable photoluminescent films. Our strict quality control measures, tremendous capability, and unmatched expertise in the material reflective industry make us your one-stop supplier of long-lasting photoluminescent films.

XW Reflective produces two types of photoluminescent films. They are PVC and PET photoluminescent films.

An example of our PVC photoluminescent film is the digital print photoluminescent film XW10-31. PVC Digital Print Photoluminescent Film has PVC as its face film and phosphor powder as its glowing element. The PVC luminescent film absorbs natural or artificial light and glows in the darkness. PVC is the best material for digital printing and this makes it perfect for decoration signs, advertisement signs, and emergency signage in buildings.

PVC Type Photoluminescent film for Printing

Plotter cutting glow-in-dark tape XW10-11 is an example of our PET photoluminescent film. It has PET as face film and luminescent powder as its glowing element. PET is a perfect material for plot cutting and is suitable for producing a glow in dark signs like EXIT signs.

PET Photoluminescent film Type for Lettering

XW Reflective produces high-quality photoluminescent films that meet all your requirement. We use high-quality face films to produce first-class photoluminescent films that guarantee the best results you desire. We have highly advanced machines that enable our highly-skilled, expert, and experienced workers to produce durable and virtually impressive films. Contact XW today and our highly dedicated team will be excited to assist you with all your photoluminescent film needs.

Photoluminescent films have several advantages, which include the following. They are

- Non-radioactive

- Non-toxic

- Meet Photoluminescent Safety Products Association

- Easy to cut and operation

- Self-adhesive.

- Durable

Below is a detailed product description of our PVC Digital Print Photoluminescent Film.

- Glowing Element: Phosphor glowing powder

- Durability: Indoor 10 years

- Roll Sizes: 1.24M (W) x 45.7M, 48” (W) x 50 yards

- Customized Width: Up to 124 cm

- Film Thickness: 270 mic

- Face Film: PVC

- Adhesive: 40 mics permanent pressure-sensitive adhesive

- Release Liner: 130 GSM Poly-coated paper liner

- Application Surface: Flat surface only such as aluminum

- Application Temperature: 15℃ or higher by any of the following methods:

- Mechanical squeeze roll applicator

- Hand squeeze roll applicator

- Hand application is recommended for copy only

- Glowing Hours Availability

| Product Code | XW10-31 | XW10-32 | XW10-33 | XW10-34 | XW10-35 |

| Glowing Hours | 2-4H | 4-6H | 6-8H | 8-10H | 10-12H |

PVC Photoluminescent Film

The photoluminescent pigment is coated onto PET vinyl to form Glow in Dark Tape. It absorbs light and glows in darkness by emitting its absorbed light energy.

Below is a detailed product description of PET Plotter Cutting Glow in Dark Tape.

- Glowing Elements: luminescent powder

- Durability: Indoor 10 years

- Roll Sizes: 1.24M (W) x 45.7M, 48” (W) x 50 yards

- Customized Width: Up to 124 cm

- Glowing Hours Availability

- Film Thickness: 230 – 240 mic

- Face Film: PET

- Adhesive: 40 mics permanent pressure-sensitive adhesive

- Release Liner: 130 GSM Poly-coated paper liner

- Application Surface: Flat surface only such as aluminum

- Application Temperature: 15℃ or higher by any of the following methods:

- Mechanical squeeze roll applicator

- Hand squeeze roll applicator

- Hand application is recommended for copy only

- Glowing hours availability

| Product Code | XW10-11 | XW10-12 | XW10-13 | XW10-14 | XW10-15 |

| Glowing Hours | 2-4h | 4-6H | 6-8H | 8-10H | 10-12H |

PET Photolumiscent Film

Photoluminescent films have many unique and numerous applications. Below are some of the unique applications of photoluminescent films.

- Evacuation guidelines signs

- Fire extinguisher signs

- Emergency and exit signs

- Glowing stickers

- Building material signs, including handrails, tape application

- Personal protective material, including bikes, helmets

- Toys and stationary

- Interior decors

Photoluminescent Film Applications

Because of its tremendous benefits and super unique applications, photoluminescent films are widely used by many industries. The following are some of the top industries that use glow in darkness or photoluminescent films:

- Automobile Industry

- Manufacturing Industry

- Transport & logistic Industry

- Pharmaceutical Industry

- Food & Beverage Industry

- Construction Industry

XW Reflective supplies highly efficient and value-added glow in darkness films for the above-listed industries and other general industries. No matter the industry you find yourself in, we can supply you with excellent and highly appealing photoluminescent films. You can contact our highly dedicated team and they will be excited to assist you to select the best films for your project.

We have a very effective system that enables us to supply your ordered photoluminescent films quickly. When you order our photoluminescent films, they will be shipped to you within 3 days if we have enough stock. It takes 7-10 working days to ship out your ordered films when we don’t have enough stock. Samples can be shipped to you within 3-5 working days once we receive your requests and reach an agreement with you.

As one of the leading photoluminescent film producers in the world, our utmost priority is to manufacture high-quality films for our customers. We follow high-standard production procedures for our operations. XW Reflective produce high-quality glow in dark films by doing the following:

- Raw materials inspection: We conduct a thorough raw material inspection to ensure only high-quality raw materials are used for p We use quality face films, release paper, and glow powder to produce our glow-in-dark films.

- Strict production inspection: Our Quality Control team cuts production samples and strictly inspects them at our well-equipped lab. They use our modern lab equipment to check properties like brightness, thickness, and stretch. QC uses the brightness detector to check for product brightness at the production line.

- Final product inspection: We test samples of the final photoluminescent films produced to ensure only high-quality films are supplied to our customers.

- Highly skilled staff: We have a highly skilled staff who have been trained to work by our high-quality production standards.

- Highly advanced machines: XW Reflective has highly advanced machines that guarantee the production of precise and high-quality photoluminescent films.

XW Reflective is your one-stop photoluminescent film supplier. You should choose us because:

- We have 10 years of experience in the reflective material film industry

- We are ISO7591 Certified Factory

- We have the strong production capability

- We operate by high-quality control standards.

- We offer high-quality and value-added photoluminescent film products and services.

- We have highly advanced machines.

- We offer first-class customer service.

We mainly offer our products to businesses but we can also deliver to individuals.

Our minimum order quantity is 10 rolls. However, we accept the trial orders.

We mainly offer our products to businesses but we can also deliver to individuals.