Project Description

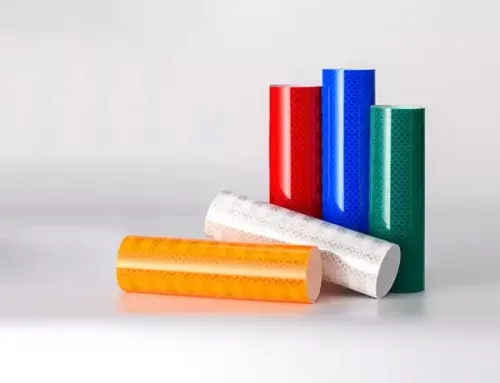

Reflective Sheeting Production

XW Reflective is a leading manufacturer in the reflective material industry, providing top-quality prismatic reflective sheeting and micro glass reflective film to distributors worldwide.

With a strong commitment to both quality control and production time, XW Reflective consistently delivers excellent service to every reflective self-adhesive vinyl customer.

Prismatic reflective sheeting is one of our standout products, made from a variety of materials including acrylic and PMMA. Whatever your reflective material needs, XW Reflective has the perfect solution for you. With different materials suitable for digital print, screen print, and plotter cutting, features are durable and easy to paste.

With XW Reflective, you can be confident that you are getting the highest quality reflective material on the market.

Prismatic Reflective Sheeting Description

Discover our cutting-edge HIP reflective sheeting designed to revolutionize road safety. High-Intensity Prismatic (HIP) technology ensures superior visibility, making it an ideal choice for highway traffic signs, directions signs, road signs, and signage.

Our HIP reflective sheeting boasts remarkable durability and weather resistance, ensuring long-lasting performance in various conditions. With its exceptional retroreflective properties, it enhances the visibility of objects during nighttime and adverse weather, reducing the risk of accidents.

Engineered to meet the highest industry standards, our HIP reflective sheeting guarantees compliance with road safety regulations. Its easy application and cost-effective nature make it the go-to solution for transportation agencies, construction companies, and safety-conscious individuals.

If you are interested in our prismatic reflective film for direction signs, and road signs, please contact us for a quotation now.

Technical Data

- Retroreflective Elements: prims

- Durability: 10 years outdoors by the specialist application (under vertical outdoor exposure)

- Roll Sizes: 1.22M (W) x 45.7M, customized width is up to 1.23m.

- Min Coefficients of Retroreflection (Ra)

| Obs. Angle | Ent. Angle | Min Coefficients of Retroreflection (cd.lx-1.m-2) | |||||||||

| white | yellow | red | green | blue | brown | orange | fluorescent yellow-green | fluorescent yellow | fluorescent orange | ||

| 0.2° | -4° | 375 | 262 | 75 | 67 | 30 | 18 | 150 | 200 | 150 | 75 |

| 0.5° | -4° | 142 | 99 | 28.5 | 22.5 | 11 | 7.5 | 57 | 75 | 55 | 30 |

Application

High-intensity prismatic (HIP) reflective sheeting finds extensive application in various road safety and traffic management scenarios. Its advanced reflective technology and durability make it an ideal choice for the following purposes:

- Warning Signs: HIP reflective sheeting is extensively employed for warning signs on roads and highways. These signs include “Caution,” “Danger,” “Slippery When Wet,” and “Construction Ahead” signs, among others. The high visibility of HIP sheeting ensures that drivers are promptly alerted to potential hazards, reducing the risk of accidents.

- Information Signs: HIP reflective sheeting is used for informational signs, providing essential details to drivers and pedestrians. These signs may include “Rest Area,” “Gas Station Ahead,” “Tourist Attraction,” and other informative markers, helping travelers make informed decisions during their journey.

- Highway Road Signs: HIP reflective sheeting is a common choice for various highway road signs, such as speed limit signs, lane control signs, route markers, and exit signs. The enhanced visibility of these signs ensures that drivers can easily navigate and comply with traffic regulations.

- Barricade Zones: Temporary barricades and construction zones require enhanced visibility to alert drivers and pedestrians of potential hazards. HIP reflective sheeting is often used on barricades to improve visibility, especially during low light conditions and nighttime, reducing the risk of accidents and promoting safety around construction sites.

Overall, the widespread use of high-intensity prismatic reflective sheeting in direction signs, highway road signs, barricade zones, and other road safety applications highlights its significance in promoting safety, reducing accidents, and improving overall traffic management on our roads.

Material of Reflective sheeting

Reflective material categorizes into reflective fabric and reflective sheeting. The applications are road safety and personal safety. Reflective Sheeting Signs is a reflective material dedicated to traffic signs and license plates, made of a reflective layer formed by glass beads and some polymer materials like PVC, PET, Acrylic, PC, etc.

Features of Reflective Material

Reflective material always shows in our daily life as we all know, like car license plate application, the isolation barriers on both sides of the road, and some traffic reflective signs. And reflective material has 4 points features as below:

Diversity of reflective material

In order to match the characteristics and uses of other products, reflective material is manufactured as different reflectivity, flexible, durability reflective vinyl for daily necessaries application, usually divide into road safety and vehicle registration security. Such as construction safety sign, permanent traffic sign, barricades, traffic cones, car license plate, etc.

Durability of reflective sheeting

Reflective materials generally have good resistance to outdoor aging, abrasion and adhesion. It shows no appreciable cracking, scaling, pitting, blistering, edge lifting, or curling, or more than 1/32’’ shrinkage or expansion during its outdoor life. Moreover, reflectivity remains more than 50% of original results after outdoor life.

Reflectivity of reflective material tape

Reflective material tape can reflect original light under the lighting of headlamp light or road light. I think many drivers know that when you are driving on the highway. As the name suggests, reflectivity is one of the most important characteristics of reflective materials.

It is precisely because of the reflective nature that reflective materials can provide the most effective and reliable personal safety guarantee at night or in poor sight environments.

Wide-angle of reflective material

Reflective material usually has a better wide-angle, so that reflective sheeting or reflective fabric also can keep a good reflective effect, reflect light directly even there is a wide-angle between reflective film and lighting.

This wide-angle feature of reflective sheeting is applied to the production of traffic signage and car license plate, which improves safety on your roadway with bright, easy to understand the signage.

Reflective material tape can reflect original light under the lighting of headlamp light or road light. I think many drivers know that when you are driving on the highway. As the name suggests, reflectivity is one of the most important characteristics of reflective materials.

It is precisely because of the reflective nature that reflective materials can provide the most effective and reliable personal safety guarantee at night or in poor sight environments.

The above are the four most common characteristics of reflective materials. When designing, XW Reflective factory must consider these four points into the reflective material, so that these reflective tapes can be used better in our daily necessaries.

Service life of reflective tape: 1-10 years.

Generally speaking, the service life of the reflective film is range from 1-10 years depends on the surface film and weather conditions. For example, PET as top layers, the outdoor durability is 1-3 years, as its nature of PET.

Why different in reflective sheeting signs’ using life?

With the time goes, the reflective sheeting will decrease the reflection value during the usage under the non-protective environment. So XW Reflective divides different standards for this road reflective film according to the reflective value.

Standards of reflective sheeting tape

The grade of reflective film can usually be followed by diamond grade, high-intensity grade, engineering-grade, economic grade, and other categories.

Of course, the raw reflective material using and selling price of reflective tape is different due to the different requirements of reflection value and outdoor life. For example, the high-intensity grade reflective sheeting can be used for highway reflective signs, with high reflection parameters, asked a high price. But low reflective film is enough to made as reflective street signs.

In a word, you can choose a different standards of reflective tape according to your needs.

Storage of reflective material

Road reflective sheeting film is a high-tech reflective product, a new type of functional composite material, with a rapid development in recent years in the world, play an important role at night safety. But reflective vinyl sheeting needs to be maintained well for better express its reflective function. So, we need to take the right measure to storage reflective sheeting vinyl rolls.

The first is the stacking of reflective films.

- It is best to be able to stack the carbons with reflective sheeting rolls in the same direction and horizontally in layers.

- It is strictly forbidden to stack crosses.

- It is strictly prohibited to stack reflective sheeting rolls’ cartons of different sizes together.

- Partially used reflective film rolls are required to return to the cartons with polybag protected.

- Unprocessed reflective sheets should be store flat.

- To avoid direct sunlight and damp storage environment. Reflective films should be stored in a cool, dry area, ideal at 18-24℃, and 30-50% humidity and should be applied within one year of purchase.

In fact, we also need to pay attention to a small detail before stacking, which is to handle lightly when handling to avoid collision. And check whether the package is damaged before handling.

Application of reflective sheeting:

Reflective sheeting is mainly used for various road and railway permanent or temporary traffic signs, construction zone signs, vehicle license plates, barricades, helmet stickers, etc.

The operating temperature of the reflective film sheeting:

Generally, reflective sheeting incorporates a pressure-sensitive adhesive and should be applied to the sign substrate, such as metal or aluminum at a temperature of 65°F / 18 ℃ or higher.

Leading Time of Prismatic Reflective Sheeting

- We have regular stock of reflective sheeting products for sale in the warehouse, if not, it will take 7-10 days to arrange reflective material production & shipment after deposits receive. Thus, please confirm with the XW Reflective manufacturer before ordering our reflective tape material.

OEM & ODM

- Customized reflective sheeting width available( Can’t over the Maximum width).

- Customized reflective vinyl sheeting package mark service.

- For any clients who want to print LOGO on retro-reflective film, please contact our staff and requests a high quantity.

- For orders less than 100 rolls, we can do OEM Cartons and Product mark

- To order more than 100 rolls, and request your own logo, it needs one more deposit: USD 800 for the cylinder cost

Quality Control for Reflective Sheeting

-

Raw reflective material inspection

XW Reflective has strict quality control for reflective sheeting material production, from face film to release paper, all the manufacturing material of reflective tape vinyl will be strictly inspected before putting into production.

XW Reflective always checks reflective manufacturing materials and must ensure this raw reflective vinyl sheeting is in line with the standard of reflective vinyl stickers production, then take away the disqualified raw reflective material, finally, XW Reflective will arrange reflective sheetings manufacturing by the leftover reflective initial material.

-

Reflective material check during production

QC will cut production samples, bring them to our own lab then inspect brightness, stretch, thickness, etc.,also they will bring a Brightness detector to the production line and check for brightness.

XW Reflective arrange 3 technical staff to inspect reflective tape manufacturing in every reflective material production line, they can take measures quickly and adjust reflective sheetings production once reflective pinstripe tape production occurs some quality problems, in addition, they will paste poor quality signs on these problem reflective products, deliver them to QC lab for a quality analysis.

-

Final inspection of reflective material

When Rolling the final product, workers will check and remove the poor-quality sheeting and mark the joint. Each joint we arrange extra reflective sheeting for clients. If the joints are out of the allowable range, we label the roll as B grade.

We will sample-test the final product and also do an inspection at the client’s request.

After-Sales

XW Reflective tries our best to reduce the quality problem for our reflective vinyl, but if you still find a quality problem in our heat reflective fabric, please don’t hesitate to contact us for the best after-sale service, and XW Reflective will provide the best after service until you are satisfied with our service.

If you find your product has poor quality reflective material – whatever how many they are. Take a picture or video of it, show us and our team will reply within 24 hours.

Package of reflective sheeting

- Inner packing: inner film + Plastic Bag + 2 pc Plastic Plug

- Outer packing: 5 layers carton box with carton sealing nail

| Model | Size (M) | Carton (M) | N.W. (KG) | G.W. (KG) | 20GP (Roll) |

|---|---|---|---|---|---|

| XW9201 | 1.22*45.7 | 1.31*0.21*0.24 | 20.8 | 24.2 | 360 |

- *This data is only for reference

- *Please contact our staff for customized products.

- *The data does include the pallet size, we recommended increasing the pallet to protect the goods.

- Loading Port: Ningbo/Shanghai or other China port

Storage of reflective material

- Reflective sheeting should be used in 1 year after you get the reflective sheeting tape order from XW Reflective because the reflection sheeting effect is best in the first year, if you use the reflective sheeting vinyl after 1 year, the reflection value and other parameters will have some changes different from the lastest reflective sheeting at this year.

- Please use PVC inner film to tightly packed partially used reflective sheeting rolls, then return it back to the shipping carton. The reflective sheeting package is better placed vertically, this reflective vinyl sheet placement not only can avoid distortion due to substrate buckling but also can defend against extension due to moisture absorption, in addition, vertically placed reflective sheeting can reduce the pressure to reflective vinyl during storage, avoid the pressure that may damage the reflective layer.z

- Store the reflective sheeting in a clean, dry area at 20 ℃ and 50% relative humidity and away from direct sunlight.

Recourse

- FAQs of XW Reflective

- Reflective material catalog

- Company Certification

Related product

| Model | Face Film | Durability | Size | Features |

|---|---|---|---|---|

| EGP reflective sheeting XW9201 | Acrylic | 7 years | 1.22M*45.72M

customized size is up to 1.23M |

screen printing

plotter cutting digital printing |

| Super intensity reflective sheeting XW9400 | PMMA | 10 years | 1.22M*45.72M

customized size is up to 1.23M |

screen printing |

IF YOU CAN’T FIND WHAT YOU WANT, PLEASE FEEL FREE TO CHAT WITH US ONLINE OR SENT US A EMAIL. OUR STAFF WILL HELP YOU!