Printed Reflective Fabric

XW Reflective is a leading reflective material factory in China since 1985s, the printed reflective fabric is one of our reflective products, very popular in the clothing industry.

Basic Material of Printed Retro Reflective Fabric

Printed reflective fabric refers to the fabric formed by adding special reflective material glass beads into ink resin and directly printed on T-shirt fabrics of various colors through screen printing. In places with insufficient sunlight or at night, it can play a warning role through self-illumination and reflection of external light sources.

| Product name | reflective material fabric |

| Daytime Color | Sliver printed reflective fabric |

| Reflection color | Sliver printed reflective fabric |

| Backing fabric | Customer-sized, can be supplied by customers |

| Reflectivity | R>200 CD/LUX |

| Home wash cycles | 25 cycles ( 60°C/140°F ) |

| Width | Up to 140CM, can be customized |

| Certification | OEKO-TEX 100 |

Printed Retro Reflective Fabric Products

The printed retro-reflective fabrics are widely used for casual clothing, reflective jacket, which can make you eye-catching at night on the street, also can be made as safety clothing for a night runner or kids. We provide printed reflective fabric as below, we also provide customized service. Anyway, if you are looking for a quality retro-reflective fabric supplier, please feel free to contact us for more details.

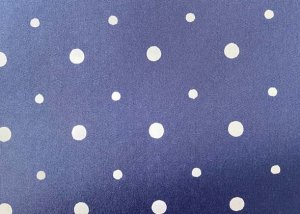

XW8011 Dots Pattern Printed Reflective Fabric for Hats

XW Reflective is a leading reflective fabric supplier in China, supply this XW P8011 printed navy & silver reflective fabric in a wholesale price and top quality. And all of our reflective fabric products have a good reflective feature, can keep you safe at night. If you are interested in XW reflective printed reflective fabric, please feel free to contact us or you are welcome to visit our reflective fabric factory for more details.

XW P8003 Dots Pattern Printed Reflective Fabric for Outdoor Clothing

XW P8003 printed silver reflective fabric with dots pattern reflective vinyl fabric is in stock, the sample is navy color and the different sizes of dots pattern with reflective grey. XW Reflective develops this reflective dots fabric for clothing, in accordance with the trend of kids' clothing or casual clothing. If you have your own designs and want a customized service, XW Reflective can meet your demands too.

XW P2000 Paw Pattern Sliver Printed Reflective Fabric for Garment

XW P2000 printed reflective fabric with paw pattern reflective vinyl fabric is in stock, the sample is navy color and cute bone pattern with reflective grey, reflective fabric with a simple animal pattern is suitable for children's' cloth, not only popular in kids, but also can reflect the light to light source in the poor light environment, can remind their parents to look for their kids in the night.

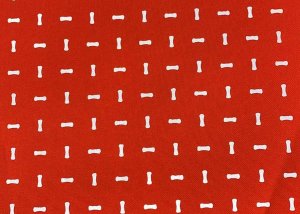

XW P1000 Bone Pattern Red Printed Reflective Fabric for Outdoor Clothing

XW P1000 printed reflective fabric with bone pattern reflective vinyl fabric in stock, this hi-visibility color and cute pattern reflective fabric can be made for safety clothing and fashion garments as well. Moreover, XW Reflective manufacturer accepts customized backing material of printed reflective fabric according to customers' requirements, such as nylon taffeta, chiffon reflective fabric, spandex reflective vinyl, 100% polyester fleece sweatshirt, etc.

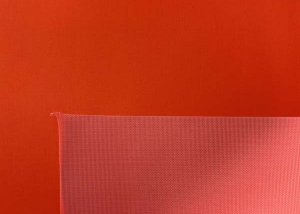

XW P6202 Fluorescent Orange Printed Reflective Fabric for Clothing

XW P6202 printed reflective fabric has fluorescent orange reflective vinyl fabric in stock, this hi-visibility color reflective fabric can be made for safety clothing and fashion garments as well. Moreover, XW Reflective manufacturer accepts customized backing material of printed reflective fabric according to customers' requirements, such as nylon taffeta, chiffon reflective fabric, spandex reflective vinyl, 100 polyester fleece sweatshirt, etc.

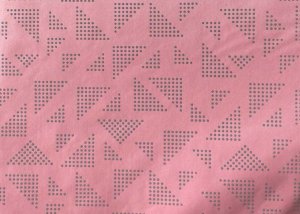

XW P8018 Triangle Pattern Printed Reflective Fabric for Fashion Clothing

XW P8018 triangle printed reflective fabric for cloth has a red and pink color in stock, with triangle dots pattern on the reflective fabric, shows a simple fashion pattern design, suitable for casual clothing, fashion clothing, reflective jacket, safety vest, reflective clothing, reflective sportswear.

XW P8015 Irregular Line Pattern Printed Reflective Fabric for Outdoor Clothing

XW P8015 printed reflective fabric has many pretty designs that supplied from XW Reflective manufacturer, can meet kinds of requirements of the reflective jacket, safety vest, reflective clothing, reflective sportswear. And XW Reflective also has enough ability to accept customized design on the printed fabric if you can make enough order quantity.

XW P8005 Phoenix Pattern Printed Reflective Fabric for Sportswear

XW P8005 printed reflective fabric has many pretty designs that supplied from XW Reflective manufacturer. And this reflective fabric shows different colors in a day, grey in the daytime, white in the night time when there is a light source. Printed reflective fabrics are ideal for use as timing, lining, and apply for safety garments, fashion clothing, sportswear, etc.

♦ Production Process of Printed Reflective Fabric:

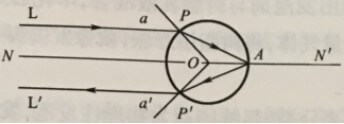

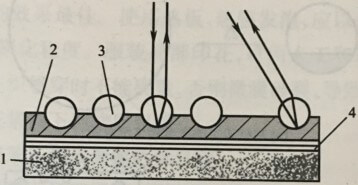

The principle of reflective printing is to print spherical lens glass beads (composed of silica, barium oxide, zinc oxide, etc.) on the fabric surface. The glass beads refract, reflect and refract the light on the fabric, so that the incident light returns to the direction of the light source. The color paste composition of reflective printing includes reflector, cross-linking agent and colorant (proper amount).

A mixture should have strong film-forming property and high transparency, in order to improve the fastness of the product, crosslinking agent can be added if necessary. The reflection intensity of reflective patterns printed with different color pastes is different.

The darker the color of general colorants is, the stronger the ability of absorbing light is, and the lower the corresponding reflective intensity is. The process of reflective printing is similar to pigment printing. After printing, it is dried at 100-105 ℃ and then baked at 150 ℃ for 3 min

♦ Advantages Compared with Screen Printing and Heat Transfer

| Feature | Reflective Printing | Silk Printing |

| Productivity | High | Low, Plate hole easily get blocked |

| Washing Durablity | High | Very low |

| Reflectivity | High | Low |

| Feature | Reflective Printing | Heat Transfer |

| Product Cost | Low | High |

| Continuous | Yes | No |

♦ Two types of printing fabric for you

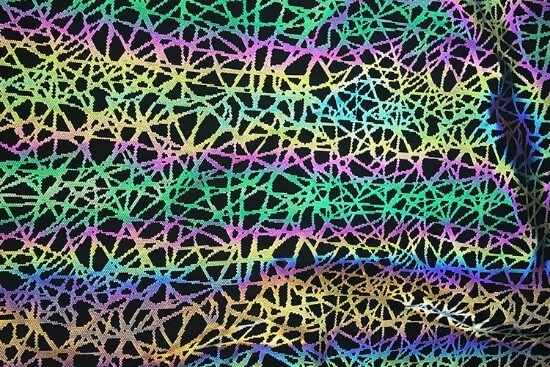

XW Reflective provides both silver printed reflective fabric and rainbow printed retro-reflective fabric to you, you can choose bright reflecting silver colors or rainbow reflecting color.

Silver Reflective Printing Fabric

Rinbow Reflective Printing Fabric

Application Fields of Printed Reflective Fabric:

Reflective fabrics can be used in traffic safety equipment, uniforms, work clothes, protective clothing and other clothing related to the safety of people’s life and property. It can also be used to make raingear, reflective raincoat, reflective sportswear, reflective backpack, reflective gloves, reflective shoes and reflective hats.

CONTACT US

XW Reflective is specialized in retroreflective sheeting for decades years, if you want to know more details about us or you are looking for retroreflective materials products, please feel free to contact us for more details by the following form.

Common FAQ of printed retro reflective fabric

The special reflective material glass beads are added into the ink resin and printed directly on T-shirt fabrics of various colors through screen printing. In places with insufficient sunlight or at night, it can play a warning role by self-illumination and reflection of external light sources. Printed reflective fabric is suitable for printing various fibers.

Fig. 1 Schematic diagram of beam light reflected by sphere

L-Incident light P– Refraction point A-Specular reflection point

P`– Refracting point L`-reflected light

Fig. 2 Schematic diagram of semi buried slurry layer of micro glass beads

1-printing layer 2-paste layer 3-bead 4-coloring layer

It can be applied to different substrates

The reflective pattern can be customized

Outstanding reflective effect

Good washability