Safety is paramount in just about any workplace whether it is a manufacturing unit, a warehouse or any other type of business. You would like your workers to be safe and secure at all times and one aspect of this focus on safety can be satisfied by using glow in dark film signs. These signs are often essential in emergency situations where loss of electric power can cause a facility-wide blackout. Without such signage in position, evacuation and other emergencies can be harder to deal with and may result in unsafe working conditions.

When there is a fire in the building, electric power is shut down and the smoke compromises the visibility, making evacuation signs difficult to read, but the photoluminescence signs make the emergency procedures and floor plan easy to read, thereby facilitating a faster and more efficient evacuation. These signs are equally useful in event of storms and other situations that cause a building to lose electric power. Photoluminescence safety signs have been used with great success in the marine and aviation industry for many years.

How does Photo Luminescence Material Work?

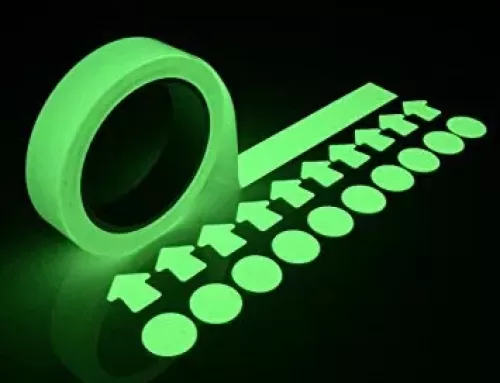

Photoluminescence safety signs are powered by ambient light and are designed not to light up space but define a space and ensure that when an emergency arises people can find their way to safety with ease and confidence. The photoluminescence film luminous principle is actually through the atomic electron energy level transition. Inorganic phosphorous is used in making of the photoluminescence film which is incorporated into a carrier or substrate which pulls in energy from the surrounding light source. The substrate could be a water-based or solvent-based paint, magnetic tape, plastic extrusion, vinyl film or polyurethane casting. The phosphorous absorbs the light in visible and ultraviolet wavelengths and when placed in the dark setting releases visible light and glows. Photoluminescence signage is a lot more superior to other types of illuminated signs as it doesn’t require an outside power source to keep it illuminated in an emergency situation.

These emergency safety signs are available as rigid plastic and acrylic sheeting or in flexible glow in dark vinyl rolls. These safety signs are environmentally friendly, code compliance and can be cut into strips of various lengths and shapes for illuminating hallways, walkways, staircases and other indoor or outdoor areas. The emergency signs made of vinyl are durable, ultraviolet stable as well as fire and weather resistant.

Benefits of Photoluminescent Safety Signs

Photoluminescent signs offer various benefits over electrically wired safety signs with the most important benefit being the reliability and another great benefit is that they save energy thereby reducing carbon footprint.

Here are some other benefits of photoluminescent signs.

· Keep your Building Occupants Safe

Keeping your building occupants safe is essential in emergency situations and the use of glow in dark signs and evacuation routes in stairways help you do that because “in an emergency use the stairs” we all know that. However, most people do not know that all stairways do not necessarily lead to the exit. So, installing these safety signs with a name or number along with floor indicator and exit information allows the occupants to navigate to the nearest exit safely.

· Provide Assistance to Fire Responders

When fire responders enter your building they need to create a mental map in their heads to connect their current location with their destination. Police, firefighters, and other emergency responders can rely on these signs to know where they need to go. These self-illuminating signs show the way in light, dark, wet or smoky conditions. If an emergency worker wants to reach someone in need on the 20th floor, they need to know if the stairway will get them to that floor or not. The same is also true for evacuation routes.

· Reduce Operating Costs

Glow in dark safety signs are a cost-effective alternative to traditional signs as in they do not require electricity to keep them illuminated and can significantly reduce the electricity bill, these signs can also be installed by anyone in less than an hour saving your time and money and thereby reducing the operating costs. On the other hand, traditional safety signs require an electrical conduit which means you need to hire an electrician for maintenance and pay more for the installation.

· Longer Lifespan

While the LED illuminated emergency signs are efficient, but they need electricity to illuminate and have various components that are subject to electrical failure leading to costly repairs or replacement. The photoluminescent safety signs have a longer lifespan, they can last up to 10 years and are maintenance-free, so it makes sense to use them. Choosing glow in dark sign means you won’t need to replace them as often and save your money in the long run.

· Code Compliant

The photoluminescent safety signs meet the same code requirements and standards as that of the traditional or electrical safety signs. When installed properly, these signs are NBR 13434 code compliant and acceptable alternative to traditional safety sign models. Properly installed means, the sign needs to be installed near a light source so that it gets charged, the light source should be on at all times of building occupancy and charging light source may not be on a switched, dimmable or motion circuit.

· Reliable

Above all else, the most important benefit of photoluminescent safety signs is that they are reliable. Glow in dark signs absorb and store light emitted from regular light sources such as incandescent, fluorescent, halogen, and LED and when an emergency arises slowly releases the light over many hours directing the people to safely exit.

Installation of illuminated signs might be required by law, but these regulations vary from state to state and many workplaces choose to ensure the safety of their workers by installing glow in dark signage to clearly mark exit points and other areas in case an emergency arises due to the fact that they offer various benefits as mentioned above.

Are all of these articles written yourself or did you hire a writer?