Processing method of reflective fabric

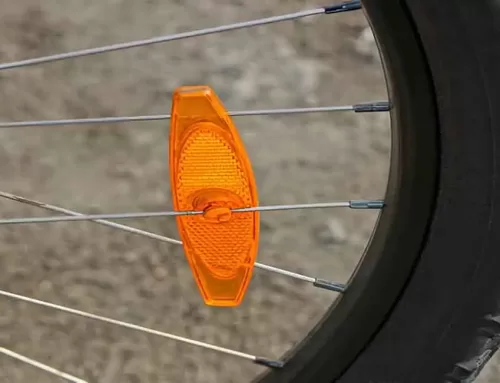

Reflective fabric is a high-tech product closely related to the safety of human life and property, widely used in clothing production, like traffic safety equipment, traffic police uniforms, work clothes, reflective promotion stickers, protective clothing, etc.

Why reflective material has reflective performance?

Reflective material is made of high refractive index glass beads, classified into the reflective fabric and reflective sheeting, the common feature is that both reflective materials can reflect the lighting at a wide-angle after a series of processing. Thus reflective material shows an excellent reflective performance whatever in daytime or night. So, if you wear the safety vest made of this reflective material, you can be easily found by night drivers no matter you are staying in the sufficient light environment or poor light situation, or long distance.

The emergence and production of reflective materials have successfully solved the night driving frustration of “seeing” and “being seen”

Reflective fabric manufacturing processes:

- Reflective glass bead coating:The so-called bead coating method is to mix the glass bead and the adhesive to form a coating paste, which is coated and scratched on the fabric. According to the different technological processes, it can be divided into multi-channel processing and one liquid processing.

- One coating one processing method: This method is to mix all kinds of materials needed for multi-layer structure in retro-reflective processing, including glass bead (or plastic bead) reflective materials, coloring pigments, adhesives, etc. Now the ink which we commonly use is called “global series” ink, the ink is made into printing paste or coating paste. After a coating or printing process, the coating is printed on the cloth, so we can get the reflective products.

- Bead planting:The bead planting method is an electrostatic bead planting method, which uses high-voltage electricity to generate a strong electric field to make glass beads charged and adsorbed on the fabric; It is also a method of spreading glass beads evenly on the fabric coated with an adhesive or a method of sticking glass bead to cloth through glass bead groove. Process flow: raw fabric → primary coating or dip coating → Apply reflector → Apply adhesive→ Pearl planting → Post treatment。

- Transfer method:Transfer substrate → Pretreatment → Bead arrangement → heat treatment → reflective layer treatment → coating or printing treatment;

- composite fabric → stripping → post-treatment.

- Hot melt back coating → Composite protective material →film product → transfer to fabric. This technology is mainly used for products related to road traffic safety, widely used in reflective clothing, all kinds of occupational clothing, work clothes, fashion clothes, shoes and hats, gloves, backpacks, personal protective equipment, outdoor products, etc. And also, it can be made into various reflective products, reflective scalding, and ornaments.

XW Reflective is a leading reflective material supplier, has our won reflective fabric factory, with 35 years’ manufacturing experience, if you are interested in reflective fabric, or you want to know more about the reflective field, please contact us for more details.