Tips to Know Reflective Trailer Tape

If you’re looking for a way to increase your visibility, reflective tape can be a great solution. The tape works by reflecting light from one direction back to the original source. This is similar to how you throw a ball against a wall. As long as all parties have lights, reflective tape can help increase visibility.

The reflective tape you choose should be easy to apply, and it should have a strong adhesive. It should also have abrasion resistance. The more durable the reflective tape, the better. It should also have a minimum overall width of 2 inches. If you’re looking to make your vehicle more visible, you should choose a tape with a reflective pattern.

Reflective tape has many benefits. It can improve visibility in low-light conditions and highlight the edges of steps and support posts. It can also help highlight sudden rises or drops in the ground. This helps prevent potential falls and tripping hazards. If you’re looking for a way to increase your visibility in poor light, reflective tape may be your best bet.

What Is Reflective Trailer Tape

Reflexive trailer tape is designed to improve visibility and safety for heavy trailers on the road. The tape is reflective and bright enough to reflect other motorists’ headlights to warn them that a trailer is approaching. While trailers are often invisible until they are close to the road, the tape’s alternating red and white patterns make them more visible and help other road users determine the distance and rate of approach of the bearer.

Reflective trailer tape is used in various industries. It is used for many safety purposes, from preventing accidents in ships and boats to educating visitors and employees about hazards. The Occupational Safety and Health Administration requires that hazardous locations be marked with tape. This tape is an excellent way to inform facility visitors of potential hazards and can improve workplace safety.

DOT-approved reflective trailer tape must meet strict standards set forth by the agency. It must be at least a quarter-inch wide and have an 11-inch-wide red and white alternating stripe. Additionally, the tape must cover at least half of the trailer’s length.

Why Reflective Trailer Tape

If you’re wondering whether reflective trailer tape really works, you’ve come to the right place. It can help reduce collisions in both urban and rural areas. In both cases, reflective trailer tape has been shown to reduce crashes by more than 40%. Moreover, this material is especially effective in areas where street lights are lacking.

With reflective trailer tape, it will reduce crash injuries. Using reflective trailor tape on trailers can make a big difference in reducing side and rear impacts into trailers.

While there is no definitive answer, the results of the CATMOD tests indicate that reflective trailer tape is effective.

As a result, truckers should install reflective trailer tape on their trailers to increase visibility and avoid accidents. These reflective tapes come in a variety of colors and widths. If you’re looking for a design that will stand out in a crowd, you might want to choose striped reflective trailer tape.

Feature of Reflective Trailer Tape

The main feature of reflective trailer tape is its ability to reflect light back to its source. This is done through the use of a pressure-sensitive adhesive. It is available in many different styles and widths. You can also request a custom design if you need it for a specific purpose.

The tape can help reduce the risk of accidents involving tractor-trailers by increasing the visibility of the trailer. By reflecting headlights, the reflective tape warns other drivers of the approaching trailer. Since trailers are not visible until they are close to the road, the alternating red and white pattern of the tape can help other road users gauge how far and at what speed they are approaching.

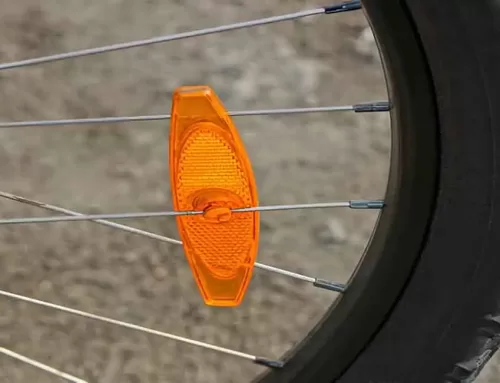

Reflective tape is designed to increase visibility in various types of lighting conditions. It can be used as a way to mark pathways, hazards, and entrances, which are often tucked away in low-lit areas. It can also be used on bicycles, motorcycles, and boats. Its high reflectivity makes it a very useful safety tool in many types of environments.

A report published by the National Technical Information Service (NTIS) evaluates the effectiveness of retroreflective trailer tape on combination trucks and heavy trailers. It also evaluates the effectiveness of the tape on side-impact crashes and rear impacts. These evaluations are based on data from 10,959 crash cases.

Requirements of Reflective Trailer Tape

When it comes to reflective trailer tape, it’s essential that it meet certain requirements. These include the type of tape used and the photometric requirements. In the United States, there are DOT-C2 and DOT-C4 tapes. Both must be at least 2 inches wide and must have a design that’s both reflective and durable.

Reflective tape should be applied horizontally, preferably 15 inches above the surface of the road. It can be in continuous bands, or placed in sections with equal spacing. Remember that you don’t need to cover the entire side length of the trailer, just enough to make it visible.

Reflective tape should be white and red, with alternating stripes. This tape must cover at least 50% of the length of the truck. According to the National Highway Traffic Safety Administration, the reflective tape helps prevent truck and trailer collisions by as much as 29%. The tape must also be placed as near as possible to the trailer’s front and rear edges.

Reflective trailer tape is a great way to improve visibility and make objects visible at night. Many government regulations require the use of this type of tape. You’ll be able to find out more about the requirements for these tapes in FMCSA section S5.7.

How to Apply Reflective Trailer Tape

Reflective trailer tape is a critical safety component of a tractor-trailer. It helps drivers see your trailer and adjust their speed accordingly. The tape has two patterns: red and white striped tape for the lower portion of your trailer and silver and white tape for the upper rear. The reflective properties of these tapes come from embedded catadioptric glass beads.

It’s important to know how to apply reflective trailer tape properly. There are several steps to follow for a smooth application. Start by preparing the surface where you will apply the tape. It’s best to use a lint-free paper towel saturated with a non-oily solvent before applying the tape. This step will help prevent any soap film from forming which will inhibit the adhesion of the reflective tape.

Applying reflective tape properly is essential for its durability and the validity of its warranty. Remember that reflective trailar tape should never be applied directly over fresh paint, as fumes from the paint will affect its adhesive. Apply the tape on a dry surface during a warm, sunny day. It helps if you use a small rubber roller or a plastic scraper blade to apply pressure. Avoid using a metal blade scraper because it may scratch the reflective tape.

After applying the reflective trailar tape, you should make sure that the tape is properly aligned. Remember that laying it flat can degrade the adhesive. This way, you can keep it straight during the application.

When applying reflective trailer tape, make sure to position it horizontally. It should start and end as close to the front and rear edges of the trailer as possible. It does not have to be continuous; it can be placed in segments evenly spaced. The tape should cover approximately half the length of the trailer. Ideally, the centerline of the tape should be between 15 and 60 inches above the road surface.

The first step is to install the reflective tape on the vehicle. You should apply the tape horizontally and vertically. You should also apply it in white chevrons on the back of the trailer. You should also cover the rear fenders, mud flaps, and support brackets.

How to Maintenance Reflective Trailer Tape

Reflective trailer tape is an important safety feature on a trailer. The tape should be applied to the lower rear section of the trailer. The tape should extend horizontally and start and end as close to the rear edge as possible. The length of the tape should be approximately half the length of the trailer.

The reflective tape should be visible and be free of dirt or mud. If the tape is worn or damaged, it should be replaced. Failure to meet the DOT requirements for reflectivity will result in fines and penalties. Moreover, the driver of the trailer could be held responsible if an accident occurs. To prevent such incidents, it is best to get DOT reflective tape from a reliable source. Most of the high-quality DOT tape comes with a five to ten-year warranty.

Reflective trailer tape can be expensive so it’s important to know how to properly apply it to your trailer. There are a few different ways to apply it. One method is to draw a thin line using a pencil with a long, straight edge. Another method is to use chalk that has been snapped lightly. The chalk should be white and not bright lime because it’s more difficult to clean up.

Once the reflective tape is applied, it’s essential to remove any loose residue. If the adhesive is stuck to the surface, you may need to heat it with a heat gun. Be careful not to overheat the surface. You may also want to use a razor blade to remove any leftover tape. Be sure to lubricate the blades with WD40.