Innovations in Holographic Reflective Coatings for Enhanced Visibility

Holographic reflective coatings are making it increasingly easier to see in the dark. Utilizing holographic technology, these coatings are able to reflect light and make objects visible even in low-light conditions. This makes them an invaluable tool for a variety of applications where visibility is critical, such as aviation, law enforcement, surveillance and automotive design. Holographic reflective coatings provide a number of advantages over traditional methods of enhancing visibility such as chemical luminescence or infrared illumination. For example, holographic coatings can be applied to any surface without altering its optical properties. Additionally, holographic reflective coatings can also be used to reduce glare from bright lights or create visual effects on surfaces that are not easily achieved with other techniques. With their versatility and effectiveness, holographic reflective coatings are an important innovation for improving visibility in a wide range of industries.

I. Introduction

Definition and explanation of holographic reflective coatings

Holographic reflective coatings are a form of fabric technology that offer enhanced visibility and luminosity. Generally constructed from reflective materials such as mylar, holographic fabric has the unique ability to reflect almost any kind of light and create a dazzling rainbow pattern. Typically used for fashion purposes or decoration, holographic reflective coatings are popularly placed on active and casualwear to accent design elements and reflect light correctly. With varying degrees of reflectivity, holographic technology is popular among athletes and runners who want to remain visible in low-light settings, especially when the risk of nighttime injury rises. Holographic reflective coatings are also lauded for their water-resistance capabilities and are found in many water-based applications such as marine apparel or swimwear.

The role of these coatings in enhancing visibility

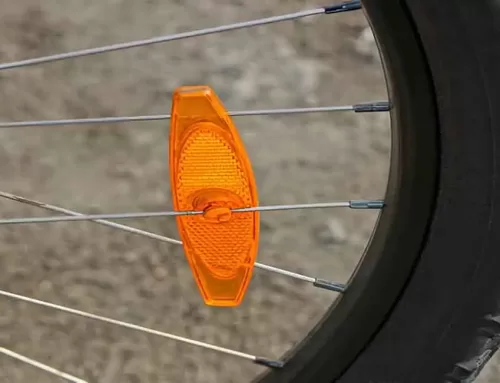

Holographic reflective coatings and reflective fabric are just two of the ways visibility can be enhanced, particularly in hazardous environments. These coatings actively reflect ambient light sources to draw attention to them and make them easier to see in low-light or foggy conditions. Not only do holographic coatings dramatically improve safety on roads and other travel paths, but they also enable people to find their way more easily during outdoor activities such as running, biking, and walking. Similarly, reflective fabric is often used around schools and universities for its highly visible attribute, allowing motorists to spot approaching children quickly and reliably. Ultimately, holographic reflective coatings and reflective fabric provide an excellent level of visibility that translates into greater safety for all manner of people going about their daily lives.

II. History of holographic reflective coatings

Early developments and applications

Holographic reflective coatings (HRCs) have a long and fascinating history that stretches back to the early-1900s, when holography was first discovered. Until recently, HRCs were mainly used to improve visibility on fabrics like reflective vests.

Now, they are applied in a number of applications across a range of industries, including automotive designs and medical instruments.

Early innovations focused on ways to produce holographic effects using hologram films that could be attached to flat objects or garment pieces.

This technology improved visibility by using photopolymers and metallic surfaces to provide reflective properties to surfaces with much greater precision than other methods available at the time.

Today, holographic coatings are used primarily in larger structures as part of advanced visual communication systems including holograms and signs.

The ever-evolving technology behind it opens up opportunities for improving visibility in a variety of industries – from fashion to signage – making holographic reflective coatings an exciting and important area for innovation.

Advancements in technology and materials

Holographic reflective coatings have been around for many years, but the modern materials used to produce them have changed significantly in recent times.

Refractive fabric was once the only material available for holography, however new synthetic materials such as polymers and metallic particles have revolutionized holographic reflectivity.

As a result, holographic reflectors now come in a wide variety of styles and finishes including ultra thin protective layers that can be applied to easily enhance an appearance without affecting its weight or shape.

Advances in technology and materials have thus enabled holographers to create stunning visuals that are unmatched in terms of their level of reflection.

III. Current uses of holographic reflective coatings

In the automotive industry

Holographic reflective coatings are being used more and more in the automotive industry. They enable vehicles to appear brighter on the outside and give them a classic metallic appearance due to their holographic nature. This technology is also being used to create holographic reflections on fabric surfaces, giving vehicles a unique look. By allowing for brighter colors and vivid holograms, these coatings can dramatically change a vehicle’s appearance, making it stand out from the other cars on the road. With this technology applied, car owners can now enjoy their own personal style within the blink of an eye!

In safety and emergency equipment

Foremost among the current uses of holographic reflective coatings are for safety and emergency equipment. This reflective fabric has a holographic approach to light reflection and requires less space, allowing for more creative freedom that can be extremely useful in an emergency situation. Holographic reflective coatings can also be used as highly visible markers or tags on clothing or equipment, making it easier to find or track in low-light environments. Future applications may include reflecting signals back to satellites, something today’s holographically reflected fabric technology has begun putting into motion at an incredibly fast rate.

In advertising and marketing

Holographic reflective coatings are proving to be a valuable asset in the fields of advertising and marketing. This form of technology is used to show holographic images on reflective fabric that can be seen at different angles under various light sources. Whether its holographic prints on t-shirts or hologram stickers on cards, these specialized coatings have become an attractive way for companies to promote their brand, product or service and draw in new customers all across the world. As holographics become more accessible, they’re sure to be used much more widely in the realms of advertising and marketing.

IV. Potential future applications of holographic reflective coatings

In virtual and augmented reality technologies

Holographic reflective coatings are an intriguing possibility when it comes to virtual and augmented reality technology.

Plus, these holographic coatings have the benefit of being thin, allowing VR and AR devices to remain lightweight while also providing noticeable holography effects.

Alternatively, retroflective fabric can be used in virtual/augmented reality applications as a more cost-effective holographic reflective coating that produces similar results.

Reflective material–such as holographic film or holographic paint–can also effectively create holography with a desired brightness and purity level. All in all, the development of holographic reflective coatings created specifically for virtual and augmented reality technology can give us exciting possibilities for the future.

In military and defense systems

Holographic reflective coatings are gaining considerable attention in the defense and military sector due to their potential to revolutionize security systems.

These holographic coatings have the capability to retro-reflect light and therefore reveal attempts of opposition movements attempting access certain area.

Owing to their holographic nature, holographic reflective coatings can be used to camouflage or conceal defense and military infrastructure from opponents, making them virtually undetectable.

This capability may potentially offer a distinct advantage in terms of defense strategy over other solutions such as retroflective fabric that can only reflect a small portion of incident radiation when compared with holographic reflective coatings.

In architectural design and construction

Holographic reflective coatings are currently revolutionizing the field of architectural design and construction.

Known to some as ‘retroflective fabric’, these modified coatings are increasingly being used on the exteriors of buildings for both aesthetic and functional purposes. They are becoming popular due to their ability to mask imperfections in surfaces, reduce heat buildup, and create holographic effects that can drastically enhance the appearance of any building.

Some architects also envision using holographic technology to generate 3D holograms that interact with the surrounding environment in real-time, adding dynamic new elements to our built environment. With so many potential applications of holographic reflective coatings yet to be explored, it is clear that this technology will continue to shape architecture in unprecedented ways.

V. Advantages of holographic reflective coatings

Improved visibility and safety in low light conditions

Holographic reflective coatings are an innovative solution for improved visibility and safety in low light conditions. Made from retroflective fabric, holographic reflective coatings serve to protect passengers while also adding a sleek and modern design element. It is also possible to choose holographic colors or patterns as part of the coating, giving it a unique look while still maintaining effective reflectivity.

The enhanced visibility itself provides considerable value to drivers navigating night-time roads, as it increases their level of reaction time when responding to hazards. Ultimately, holographic reflective coatings can be leveraged to great effect for increasing visibility and pedestrian safety in low light environments.

Enhanced aesthetic appeal

Holographic reflective coatings are an innovative and exciting advancement in fabric technology. These coatings are designed to reflect luminous, holographic designs when subjected to bright lighting environments, producing a mesmerizing and captivating effect.

Not only do holographic reflective coatings puff up the visual appeal of any garment, but they also combine protection against environmental hazards like ultraviolet rays while offering heat and moisture resistance. This makes holographic reflective coatings highly ideal for outdoor applications, meaning you can enjoy the enhanced aesthetic appeal regardless of whether it is day or night.

Durability and long-lasting performance

Holographic reflective coatings offer many advantages over other forms of reflective fabric.

Not only is holographic reflective fabric exceptionally resistant to fading, but its durability and long-lasting performance make it a great choice for various industrial, commercial, marine and personal safety applications.

Its superior reflectivity also ensures improved visibility as well as better solar radiation management in many environments.

In addition, holographic reflective coatings have been shown to provide maximum UV protection – even in the harshest weather conditions – and are highly resistant to oil, gas and harsh chemicals. For these reasons, holographic reflective coatings are often the preferred choice among architects, engineers and consumers alike.

VI. Challenges and limitations of holographic reflective coatings

Cost and availability of materials

Holographic reflective coatings are an innovative way to redefine fashion and create truly unique looks, however, their challenge lies in cost and availability of materials.

When creating holographic reflective fabrics, it can be difficult to find the combination of holographic film, fabric adhesive and reflective fabric that has the desired effect.

Additionally, more cost is associated with producing holographic reflective fabrics than with traditional fabric due to the cost of these materials.

The holograms distort light at different angles making them expensive; however, that is where its appeal lies as no two pieces are ever the same. As such, holographic reflection coatings are a great tool for fashion designers who wish to explore new techniques and attract consumers looking for something truly unique.

Complexity of production processes

Holographic reflective coatings, or reflective fabric, have become increasingly popular in the past few years due to their kaleidoscopic visuals and fantastic holographic properties.

However, these holographic materials pose unique challenges and limitations in terms of production processes.

Such holographic reflective coatings contain intricate patterns that must be formed with precision, often using difficult methods such as embossing or laminating to sculpt the holograms into the desired shape and form.

This level of complexity increases production time and labor costs significantly, which can limit the appeal of these holographic materials for some organizations.

Environmental concerns

Holographic reflective coatings offer an exciting way to revolutionize fashion, however they come with significant environmental concerns. The holographic material used to make these coatings can be toxic if not treated properly, leaving behind harmful pollutants during the manufacturing process. There is also the issue of its finite resources; the holographic fabric requires large amounts of energy in order to maintain its reflective properties and is unable to be re-used once it has been worn.

Additionally, recycling holographic material may pose a further challenge as such materials are extremely difficult to deconstruct and so their components cannot easily be reused. Though holographic reflective coatings provide beautiful and unique effects in clothing designs, their challenge of sustainability needs to be taken into consideration before using them.

VII. Conclusion

Summary of the innovations and advancements in holographic reflective coatings

The innovative developments in holographic reflective coatings have been instrumental in revolutionizing the fashion and technology industries.

From holographic material used to create clothing with an unexpected visual depth, to reflective fabric that can keep athletes safe during a workout session by providing visibility in low-light conditions, holographic reflective coatings have opened up countless possibilities for creative designs.

Not only are holographic reflective coatings a fashionable choice but also a practical one; as holographs allow for lighter, more breathable fabrics compared to traditional materials often used for similar applications; which provides wearers with comfort and protection all kinds of weathers and conditions. All in all, advances in holographic reflective coatings have demonstrated immense potential across many industries, from fashion to safety.

The potential of these coatings to revolutionize various industries and applications.

Holographic reflective coatings have the potential to truly revolutionize various industries, ranging from entertainment and automotive to consumer electronics.

As such, holographic reflective materials can be used in several applications such as in displays, reflective fabrics, and decorative holographic material designs.

While holographic reflective coatings may invigorate applications that are already present, they’re majorly expected to open up novel possibilities within the industries they become integrated with.

Thus far, holographic reflective coatings are being increasingly explored for their enormous potential but it is still unclear as to what extent they can revolutionize various industries- only time and research will tell!