REFLECTIVE FABRIC PURCHASE GUIDE

XW Reflective reflective fabrics are divided into professional retroreflective fabric tape for uniform and normal reflective fabrics for daily clothing. Our professional reflective fabric products are made of T/C, PVC, polyester and cotton material, always shown as reflective tape – reflective tape with bigger based fluorescent tape and retro-reflective tape only, reflect by micro glass beads or artificial prism. Our normal reflective fabric is shown as normal textile for casual garments, covers printed, mesh, colors even rainbow, iridescent reflective material fabric.

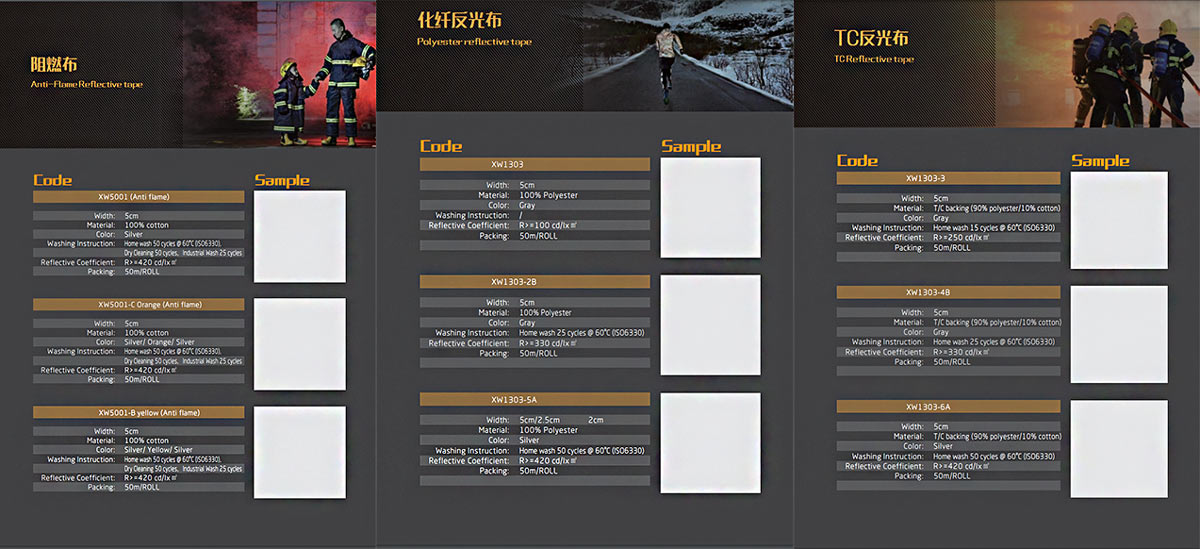

TC/Poly Backing Reflective Fabric

- For sewing on type PPE, safety workwear

- General Width: 1-140cm customized reflective TC/Poly fabric available

- Backing Material: T/C backing(90% polyester/10% cotton), which can be customized under your request

- Color: gray, silver

- Washing instruction: home wash 15 cycles@60℃(ISO6330)

- Reflective Coefficient: R>=125 cd/lx.m2

- In line with different certifications meet your demands

Reflective Webbing Ribbon

- For high visibility garments, sports gloves, bags, safety clothing, hats, pet clothes, etc.

- Width: 1.5*5cm, 2*5cm(customizable)

- Reflective coefficient: up to 420 cd/lx.m2

- Material: highlight reflective heat transfer film iron-on backing material, or reflective tape sewing on back material.

- Backing Material: Polyester, Oxford, Grosgrain tape, Webbing tape, Tricot fabric available

- Customizable Transfer Printing Reflective Webbing

FR Reflective Fabric Tape

- For safety clothing with the requirement of flame retardant

- FR Heating Transfer Vinyl Films on backing fabric

- Backing Fabric: Treatment FR cotton, Natural FR Aramid

- Washing Instruction: home wash 50 cycles@ 60℃(140°F).

- Certified by UL, SATRA, TEXTEST to comply with EN 469, NFPA 701, NFPA 2112, NFPA 1971, EN 14116, EN 20471, ANSI 107, CSA-Z96, etc.

Heat Transfer Vinyl

- For workwear, fashion cloth, T-shirt, screen printing, graphic design

- iron-on reflective stripes or logo designs and letterings

- Color: Grey, silver, holographic rainbow, and colors customizable available

- Backing Material: PES, BPU

- Shape: reflective iron-on tape, available customized shape

PVC Prismatic Reflective Tape

- Recommended use for high vis clothing, safety vest, outdoor wear, life vest, bags, shoes, etc.

- Sew on

- Material: 100% PVC

- Certification: Certified EN13356, EN 20471

- Available in any width and color, with different patterns such as W or brick shape.

- Waterproof and dustproof with high reflectivity.

Rainbow Reflective Fabric

- For sportswear, fashion apparel, reflective shoes, backpacks, etc.

- The rainbow reflective fabric also called iridescent fabric or neon reflective fabric

- Types: heat transfer vinyl, rainbow reflective fabric, printed reflective fabric with different designs, rainbow reflective tapes, etc.

- Show different reflective colors at different angles

- Available for reflective cloth or Heat transfer reflective vinyl

♦ Reflective Fabric Material Products

The retro-reflective fabrics have good reflective features, are widely used for outdoor safety reflective products and reflective safety clothing for some people who work at night or poor light environment, such as safety equipment, safety uniforms, work clothing, sanitation clothing. XW Reflective not only provides professional retro-reflective tapes, we also provide colored retro-reflective cloth, dot reflective fabric, printed retro reflective cloth, and rainbow retroreflective fabric. You can choose the suitable reflective fabric for you directly from our XW Reflective products, or contact us directly for more information.

XW2606-6A T/C Backing Reflective Tape for Safety Clothing

TC Backing silver reflective tape composes 90% polyester and 10% cotton material with micron-glass beaded coating which is intended to be used as Medium to Heavy Weight Fabrics, such as safety clothing or garments.. The reflective tape shows as grey at daytime and visible in poor light, thus to enhance the safety of anyone who wears the reflective clothing.

XW2606-4B EN20471 Certified T/C Reflective Tape

XW2606-4B tc reflective tape is intended to use on light to medium weight fabrics, such as vests or waistcoats. It is composed of micro-glass beads bonded to a polyester/cotton blend fabric backing. It reflects light directly to the original light source and enhances the visibility of anyone who wears it. The reflective coefficient (R, in cd/lux/m ) of XW2606-4B can meet the requirements in international standards.

♦Reflective Ribbon Reflective Fabric Catalogue

XW Reflective manufactures reflective tapes in a different color, different reflective coefficient and making material, they are also used for different applications, for runner, fireman or construction workers. You can download our catalog and choose the suitable one for you.

♦ FAQ GUIDE – Know More About Reflective Fabric

Here is the quick FAQ guide about reflective fabric material, you can click the question to get the answer.

XW Reflective is a leading retro-reflective fabric manufacturer in China, we supply iron-on reflective tape, sew on reflective fabric tape, fire retardant reflective fabric, etc hi-vis reflective fabric, which are widely applied in road safety, construction safety, personal safety, and road guide, for more reflective fabric applications, you can come to reflective products applications. If you are looking for a retro-reflective fabric supplier, please don’t hesitate to contact us.

Besides professional retroreflective fabric for safety clothing, XW retro-reflective fabric also contains soft, colorful, rainbow, and printed reflective fabric for fashion clothing, and casual garments. If you have any demands for reflective fabric, please feel free to contact us for more details, we’d like to serve you in the future.

Reflective safety products’ application benefits from the reflective effect of the reflective fabric tape.

So XW Reflective transfers the microbeads to the cloth base through the aluminized plant film to achieve the reflective effect of reflective fabric tape. Moreover, whether day or night, Reflective fabric always express excellent retroreflective feature, can reflect the direct light from a long distance back to the luminous place.

As we all know, there are kinds of reflective material in the market, the most common reflective fabric materials are reflective chemical fiber cloth and reflective T / C cloth.

XW Reflective is one of the leading reflective fabric suppliers in China, mainly manufacturing and providing glossy reflective clothing, high gloss reflective fabric, reflective hear transfer film, reflective fireproof fabric, reflective tape, reflective glass bead tape, elastic reflective fabric, reflective lattice belt and so on.

All of these reflective products have different features & applications, with different reflection values and parameters, already passed TUV testing and American ANSI certification, top quality exceeding European (EN471) standards.

Reflective fabrics are made of a base textile that is coated with adhesives and micro glass beads or prisms. It is running through a variety of processing technology including coatings, and composites, along with processing methods such as hot pressing. The micro-glass bead for producing high and silver reflective fabrics is half coated with aluminum to improve the reflective coefficient significantly. It reflects light back to the light source, making it an excellent material that can be used for safety and effective visibility, especially during the nighttime to identify an object.

Reflective fabrics are made of a base textile which is coated with adhesives and micro glass beads or prisms. It is running through a variety of processing technology including coatings, composites, along with processing methods such as hot pressing transfer. The micro-glass bead for producing high and silver reflective fabrics are half coated with aluminum to improve the reflective coefficient significantly. It reflects light back to the light source, making it an excellent material that can be used for safety and effective visibility especially during the night time to identify an object.

With the development of retro-reflective fabric, XW Reflective also provides colored reflective fabric for normal clothing.

Of course, the colors of retroreflective fabrics don’t have the good reflective effect same as the professional reflective fabric. The original color is the silver color after coating aluminizing, thus more colors will weak the reflective feature, the colors retro-reflective fabric can’t be used for professional safety clothing which has a high requirement for reflective feature, but colored retroreflective fabric is a good choice for fashion clothing, casual reflective jacket.

Reflective material categories into reflective sheeting and reflective fabric, reflective fabric tape applies for personal safety and fashion application. Reflective fabric always shows in our daily life as we all know, such as reflective clothing, safety vest, reflective hat, reflective bag, etc. And reflective material has 4 points features as below:

Reflective material is the category into reflective sheeting and reflective fabric, reflective fabric is aim for personal protection. Good reflective material can protect lives, typically in poor light situations, and is suitable for its application as well.

For a firefighter, it must be available for fire retardant, for a miner, it must be available for industrial washing.

For applications that don’t have such strict requirements, we’ll have more options. For example, When you need the TC reflective fabric for more than 420 cd/lux/sq. XW2606-6A silver TC reflective tape will be a good choice. However, if the material shall be industrial washable, then XW2720-6 reflective fabric tape with 25 cycles of industrial washing could meet with both requirements.

The best reflective fabric is what best suitable for the exact applications. Such as, for firefighter, the reflective material for coat must be flame retardant available. For highway traffic signage reflective sheeting, it shall be at least prismatic type reflective material, even diamond grade. For small street signage, engineer grade reflective vinyl is better. Too bright will make it difficult to tell the information printed on the signage. Then this signage will be no sense. For traffic cones, the traffic cone reflective sheeting itself is also important to decide the suitable material, like PP or HDPE.

To well match the best reflective material for its applications, we will take the following into account: printing method, durability requirements, reflection, base material, etc.

To figure out this question, you have to know that reflective and glow in the dark are two different meanings.

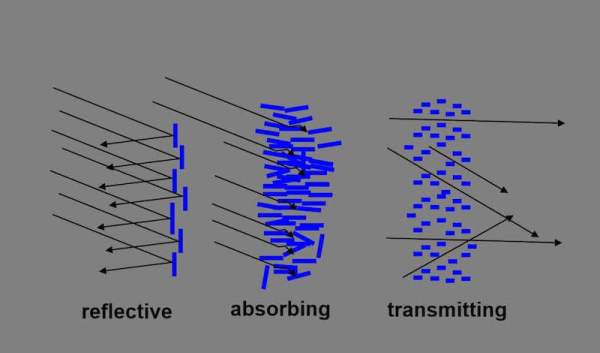

Things (surfaces) can be reflective, absorbing or transmitting.

In the case of reflective, when we talk about reflection here, we are referring to Retroreflection. Some surfaces exhibit retroreflection. The structure of these surfaces is such that light is returned in the direction from which it came. So if you need to see the reflective item, you should have light comes to the surface at the same time.

While we also have other materials, also know as photoluminescent materials which can absorb light in the daytime while giving light at dark time. They don’t need light to come to the surface to make it glow while it still can be seen without any light.

So when you see something glowing in the dark, it can be Self-luminous or reflective.

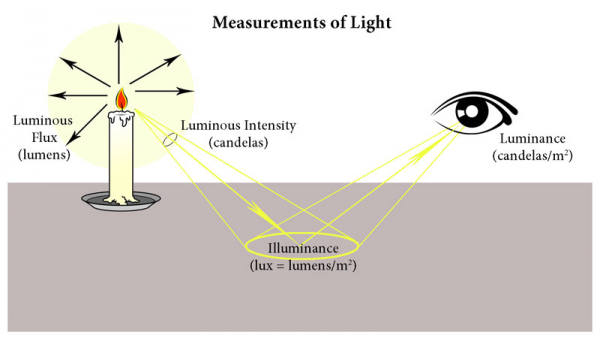

For reflective sheeting, we test by ROADMASTER according to ASTM D4956\EN12899, Observation angle: 0.2, Entrance angle: -4. While we test reflective fabric according to EN20471/ANSI107, Observation angle: 12’ Entrance angle:5.

We normally use cd/m2 to calculate the reflectivity. It indicates how much luminous power will be detected by an eye looking at a light-emitting surface from a particular angle or point of view. In this case, the solid angle of interest is the solid angle subtended by the eye’s pupil. Luminance is thus an indicator of how bright the surface will appear.

Reflective fabric is one of the essential materials for personal safety, now days, this reflective material also gets more popular in the fashion industry. Reflective tape is composed of lens glass beads with different backing fabric, the most common materials are polyester, T/C, spandex. For fashion garments, we also supply reflective heat transfer vinyl, rainbow reflective fabric, and reflective printing fabric.

In order to match the characteristics and uses of other products, reflective material is manufactured as different reflectivity, backing fabric, washing cycles reflective tape for daily necessaries application, usually divide into reflective cloth, reflective thermosensitive film, reflective yarn, reflective logo and other products for various style of application.

Reflective fabric generally requires to pass the washing cycles, normally we are talking about domestic washing cycles for most of reflective fabric. Domestic washing ISO 6330, 6n, at 60℃ for 25 washing cycles, the reflective fabric remains the minimum coefficient of retro-reflection after domestic washing cycles, rainfall, and cold temperature. Moreover, some specific reflective fabric is requiring to qualify for industrial wash, this reflective material is applied for reflective garments for oil, petrol, or mining application.

Reflective material tape can reflect original light under the lighting of headlamp light or road light. I think many drivers know that when you are driving on the highway. As the name suggests, reflectivity is one of the most important characteristics of reflective materials.

It is precisely because of the reflective nature that reflective materials can provide the most effective and reliable personal safety guarantee at night or in poor sight environments.

Reflective material usually has a better wide-angle, so that reflective fabric also can keep a good reflective effect, reflect light directly even there is a wide-angle between reflective film and lighting.

This wide-angle feature of reflective fabric material is applied to the production of reflective work clothes like uniforms of traffic police, which can well improve the personal safety in the dark situation, such as roadway, construction work zone, etc.

The reflective materials used for clothing are usually glass bead coating type. By application, which is including reflective heat transfer vinyl and reflective fabrics as follows.

A. Iron on reflective tape for clothing can be transferred to clothes by heat press machine and made into reflective clothing.

B. While Reflective fabrics are directly sewed on the clothing, made into safety clothing.

For reflective fabric, generally, we will say “silver color is the most reflective color”, as reflective fabric in silver color is >400 cd/lux/sqm for the typical reflectivity value. But not 100% guaranteed, for example (based on the comparison of the same material):

- Gray color could be easily >400 cd/lux/sq. Even golden-brown color reflective fabric could be also up to >500 cd/lux/sq.

- Some manufacturers produce the fabric “whiter”, but with very much lower reflection.

We cannot tell which color is the most reflective color, only after we checked the performance by roadmaster equipment. And sometimes, colors depend on customers’ preferences, while reflection is not the only factor influencing the decisions.

For reflective sheeting, white/silver color is the original color without painting. Color painting will cover the original reflection. Based on the same grade/quality, white/silver color is the most reflective color.

Silver is more reflective, due to the white paint coating, the white one will lose more light-reflecting, while silver is the original color after aluminizing.

Generally speaking, the service life of reflective fabric is different from reflective sheeting, reflective fabric applies for garments, vests, shoes, hats, etc, thus washing cycles for either domestic wash or industrial wash is more essential. For example, XW2606-2B polyester reflective fabric tape has 25 domestic washing cycles, whereas, XW2720-6 TC reflective fabric meets 100 domestic washing cycles.

The grade of reflective fabric can usually be followed by polyester, T/C, and aramid other categories.

Of course, the raw reflective material using and selling price of reflective tape is different due to the different requirements of reflection value and service life. For example, the aramid flame resistant reflective tape has a feature of flame and heat resistant, this is important material for fireman garments. In a word, you can choose a different standards of reflective tape according to your needs.

Reflective fabric is 50cm height a roll, you can package them in a hard carton in order, reflective fabric rolls are easy to package and storage. When you order reflective fabric from XW Reflective manufacturer or other reflective material suppliers, they will package your reflective fabric products well, therefore, you don’t worry more about extrusion deformation.

.

Reflective fabric doesn’t use single backing fabric material, usually use different backing material according to different requirements of the application. such as polyester, T/C, aramid, BPU, PES, etc. For example, elastic reflective tape XW2606-8 with backing material polyester and spandex, the process is sewing on different garments; whereas, reflective heat transfer vinyl XW8006, it is BPU backing, thus the process is hot pressing. All reflective fabric can apply for reflective clothing, reflective shirts, reflective fashion shirts, reflective vest, glow in the dark tape, security vest, reflective triangles, reflective jacket.

For a piece of reflective cloth, it contains both fluorescent fabric and reflective tape. Fluorescent color fabric is eye-catching at day time, and actually it also absorbs a little light and emits a little. Reflective fabric tape is aim to return any ray of light in the direction where it arrived, which ensures to be very well seen, the reflective tape will show visible white when there is the light source.

At night, pedestrians are easier to be overlooked by other road users due to the darkness and often adverse weather conditions. While a dark-clad pedestrian is only perceived at a distance of 25 meters, the visibility when people are wearing reflective clothes will increase to 120 meters distance to be seen by the drivers.

According to the law of safety working department like EN20471, it asks if you work when there is low light and poor visibility, especially if you are working around moving vehicles (cars, trucks or other machinery traveling under their own power – e.g., forklifts, backhoes, etc), you are asked to wear reflective clothing, even high-vis reflective clothing. So people as following are required to wear safety clothing.

- Roadway construction, utility, forestry, or railway workers.

- Utility workers.

- Survey crews.

- Forestry workers.

- School crossing guards.

- Parking and/or toll gate workers.

- Airport baggage handlers and ground crews.

- Emergency response personnel.

- Members of law enforcement.

- Accident site investigators.

- Railway workers.

Reflective fabric for clothing is made of substrate, composite glue, reflective layer, and glass beads, which can reflect the stronger light back to emission lighting, enhance the visibility of people who wear it, and remind others to pay more attention to the reflective clothing wearer.

Every year, many employees are injured or die in accidents involving moving vehicles or machines within their workplaces because their presence was not signaled appropriately. Many accidents are also caused by insufficient visibility of individuals moving along the roads. The safety of people who are at risk of being hit by moving vehicles and objects may be increased by using reflective clothing characterized by appropriate properties and design and selected appropriately for conditions in which the presence of people needs to be signaled.

Not only does this clothing make it easier for motorists to see workers at night, but it also makes them more visible to motorists during the daytime, particularly in inclement weather when inclement weather is an issue. High-visibility clothing reduces the risk of accidents and improves safety overall.

High-visibility items allow you to be seen by the drivers of those vehicles sooner and more readily. This fact increases your safety at work. The human eye responds best to large, contrasting, bright, or moving objects. Worker visibility is enhanced by high color contrast between clothing and the work environment against which it is seen.

We also have more reflective fabric for Fashion Cloth used. Please CONTACT US and let us help.

Thanks in advance.

We strongly recommend handling the reflective fabric with protected gloves and keep them in the environment of below 26.7℃ and 30 -50 % relative humidity.

Reflective clothing the main function is to enhance the visibility of people who wear it under poor light environment, and the high visibility can remind drivers to keep away from the pedestrians. Of course, the reflective tape on the clothing always shows the frame of traffic police to help the drivers see clearly the traffic gesture, therefore, the reflective clothing is widely made as work clothing.

Reflective fabric clothing for many people are not recognized in your everyday wearing, people who are wearing reflective clothing are staff from the airport, construction site, road site, mining, etc. From the research, accidents also happened from not seen by drivers, especially joggers, cyclists, pedestrians. Thus, to have reflective clothing is to been seen and visible for drivers on the road, no matter daytime or nighttime.

- Traffic Police

- Firefighter

- Joggers

- cyclists

- pedestrians

- Pets

- Kids

Yes, you can wash your reflective clothing by machine or hand wash. BUT no bleach or fabric softener, just use a mild detergent.

Reflective clothing nowadays is not for safety and visible purpose, but also the type of fashion icons. Reflective clothing is made of normal cloth and reflective fabric tape, the reflective fabric range many kinds, such as polyester or TC reflective tape, fire retardant aramid reflective fabric, reflective heat transfer vinyl tape and rainbow reflective fabric are popular in fashion areas, such as T-shirt.

Yes, you can use a machine to wash the reflective jackets. BUT no bleach or fabric softener, just use a mild detergent.

The reflective shoes are normally made of reflective heat transfer vinyl by hot processing. If there is dirt, you can dampen a soft cloth in cold water. Rub some mild soap into the cloth. Brush the soapy cloth over the reflective material. You can scrub harder if the job requires, but most dirt and grime should come right off without much struggle. Put shoe aside and allow it to dry thoroughly at room temperature.

You can dampen the stain and rub in dishwashing detergent, or baking soda. Then wash the jacket in warm water with laundry soap, stay in 15 minutes, and wash away by warm water.

The reflective jacket is one of reflective clothing, the function is to be seen while you are in the poor light condition, thus we are also called high-visibility clothing, it is not only for safety purpose, but also fashion icons.