Prismatic Reflective Sheeting

XW Reflective is a professional prismatic reflective sheeting supplier & manufacturer in China, providing high-intensity prismatic reflective sheeting(HIP reflective film) and engineer grade prismatic reflective sheeting(EGP reflective film) for traffic signs as well as prismatic reflective tape for truck conspicuity tape.

Prismatic reflective sheeting is made of artificial prisms and plastic film, with the reflective feature, which can reflect the light back to the headlamp, widely used for traffic signs such as road safety products. The reflective prismatic sheeting is composed of the wide-angle prism, which is the key element to reflect the light back to the headlamp. The prism structure is designed in a special way to ensure high reflection and wide visibility even under severe conditions.

Engineer Grade Prismatic Reflective Sheeting

- Size: 1.22*45.72m/roll, customized size available

- Colors: white, yellow, red, green, blue, orange, brown

- Application temperature: 18-28℃

- Features: high retro-reflectivity, high durability, easy to clean, cost-effective

- Durability: 7 years

- Applications: Traffic Control, guidance, warning & information sign

- ASTM D4956-17, Type Ⅱ

High-intensity Prismatic Reflective Sheeting

- Size: 1.22*45.72m/roll, customized size available

- Colors: white, yellow, red, green, blue, orange, brown

- Application temperature: 18-28℃

- Features: high retro-reflectivity, high durability, tearable

- Durability: 10 years

- Applications: Traffic cone, guidance, warning & information signs, conspicuity tape

- ASTM D4956-17, Type Ⅲ

Super-intensity Prismatic Reflective Sheeting

- Size: 1.22*45.72m/roll, customized size available

- Colors: white, yellow, red, green, blue, orange, brown,fluorescent yellow-green, fluorescent yellow, fluorescent orange

- Application temperature: 18-28℃

- Features: High brightness, long lifespan, easy installation, printable, and resistant to deformation

- Durability: 10 years(fluorescent color is 3 years)

- Applications: municipal roads, airport, high-grade highways, urban road signage

- ASTMD4956-20, Type IV

Diamond Grade Prismatic Reflective Sheeting

- Size: 1.22*45.72m/roll, customized size available

- Colors: white, yellow, red, green, blue, orange, brown,fluorescent Yellow-Green, fluorescent Yellow, fluorescent Orange

- Application temperature: 18-28℃

- Features: High brightness, long lifespan, easy installation, printable, and resistant to deformation

- Durability: 10 years(fluorescent color is 3 years)

- Applications:airport, high-grade highways, urban road signage

- ASTM D4956-20, Type V

Prismatic Reflective Sheeting Products

Super Intensity Prismatic Reflective Film XW9400

Designed to meet the demands of modern road infrastructure, super-intensity prismatic reflective sheeting boasts exceptional features that enhance its performance and value. With a focus on quality, this reflective sheeting incorporates advanced screen printing techniques, ensuring clear and crisp graphics that communicate essential messages to drivers effectively.

High Intensity Prismatic Reflective Film XW9300

Discover our cutting-edge HIP reflective sheeting designed to revolutionize road safety. High-Intensity Prismatic (HIP) technology ensures superior visibility, making it an ideal choice for highway traffic signs, directions signs, road signs, and signage.

EGP Prismatic Reflective Sheeting XW9201

Prismatic reflective sheeting is a highly sophisticated and advanced material used for enhancing visibility, particularly during low-light conditions. Mainly used for high-grade highway signs, urban road signage, etc.

Applications of Prismatic Reflective Sheeting Vinyls

Prismatic reflective sheeting has wide application in road safety products the same as micro glass beads retroreflective sheeting film. The micro prismatic reflective film is a reflective material made based on the principle of refraction and total reflection of a cube corner. 10,000 micro-prisms are a reflective product completely realized by ultra-precision mechanic technology and craftsmanship. Compared with glass microbead reflective film, it has a better reflective effect, longer visual distance, and better recognition effect, and is generally used for road signs on high-grade highways.

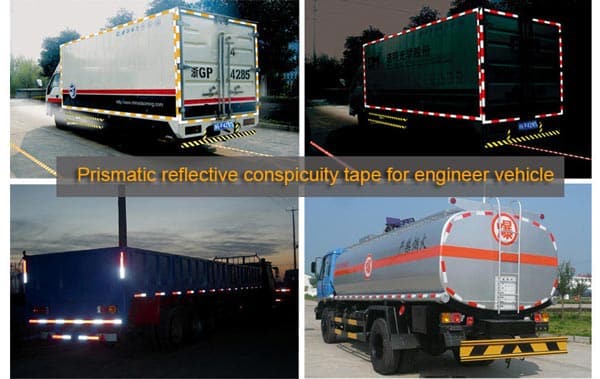

Prismatic Reflective Conspicuity Tape For Engineer Vehicle

Prismatic Reflective Sheeting For Information Signs

Prismatic Reflective Barrier Sheeting For Traffic Cone

Prismatic Retroreflective Vinyl For Warning Signs

Production of Prismatic Reflective Sheeting Vinyls

Product Compositon: from inside and out, prismatic reflective sheeting is made up of release paper, glue(PSA or Hot Melt Adhesive ), pvc film, micro prismatic reflective layer and acrylic film.

How To Produce Quality Prismatic Reflective Film?

XW Reflective is a leading prismatic reflective vinyl manufacturer in China, we know the importance of retroreflective sheeting to road safety. So we always supply quality reflective film to our customers worldwide for traffic signs, and road signs. Let’s come to know more about our production and quality control.

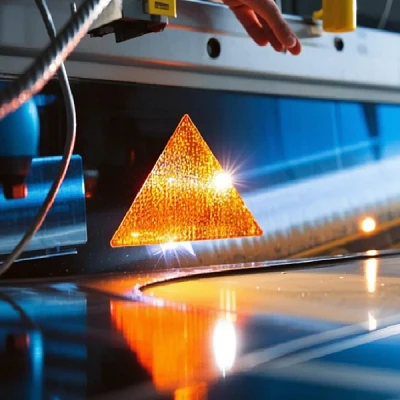

Create Prism Design On the Film

To use the model to press the specific micro prism designs on the film, then apply the reflective coating on the film, to make the prismatic reflective sign sheeting get a superior reflection feature. When the car comes, the reflective traffic signs can reflect the lighting from different angle, ensuring the road safety.

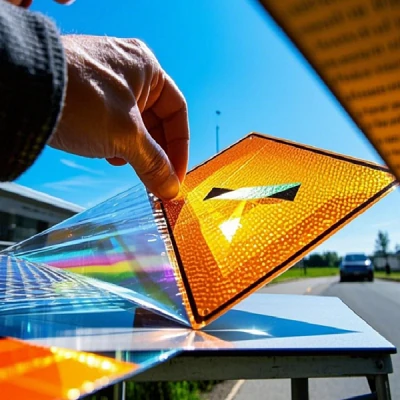

Apply Face Film On the Surface

A face layer is laminated on the top of the micro-prismatic structure. The protective layer is applied to the surface of the reflective film by coating an adhesive or hot pressing. The material is usually acrylic film, which is the best material of UV protection and waterproof.

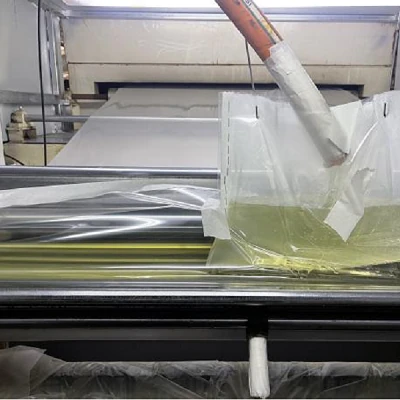

Apply Glue On the Release Film

The release film is anti glue, we put the glue on the release film by running a roller machine, then make the glue on the release film evenly, and dry on the film. Release paper is used to prevent the adhesive layer of the reflective film from being contaminated or damaged.

Combine the Release paper & Reflective Film

The reflective film consists of multiple layers, including the prismatic design, reflective coating, and protective film. This step is to put the glue on the prismatic reflective sheeting film vinyl, ensuring that the reflective coating and the protective film will adhere securely to the film’s surface.

How Is the Quality of Microprismatic Reflective Sheeting Tested?

We test the quality of prismatic reflective sheeting according to our production process. Simulate production and use process to test quality of reflective material (Test standard:GB/T 18833-2012).

Reflective performance

- Purpose: test coefficient of retro-reflection

- Test Instructions: use American 932 for testing the retro-reflective coefficient of the reflective film according to the ratio method, substitution method or direct luminous intensity method specified in JT/T 690.

- Significance of practical application: if the retro-reflective performance of the reflective film decreases, drivers may not be able to recognize the signs in time at night or in low visibility conditions, leading to traffic accidents.

Appearance quality

- Purpose: test surface flatness

- Test Instructions: use microscope to check surface flatness, regularity,cracks,stain.

- Significance of practical application: cracks and stain causes light to be blocked or absorbed, thereby reducing the reflective efficiency of the prismatic film.

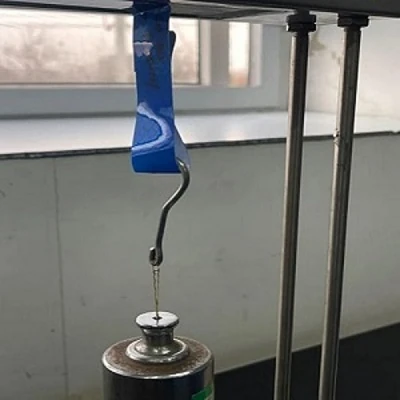

Viscosity

- Purpose: test viscosity of glue

- Test Instructions: fold the film in half and stick it together. Hang a weight and see how long it slides down after 24 hours.

- Significance of practical application:if the adhesive viscosity of micro-prismatic reflective sheeting is poor, it may cause the film to peel off or not bond properly to the target surface.

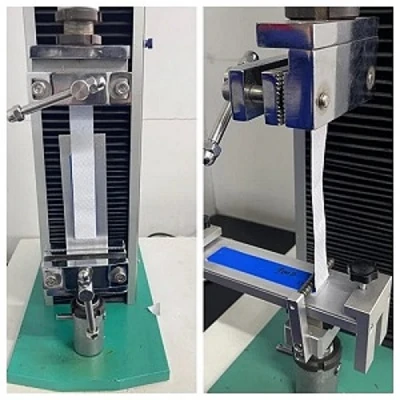

Tensile performance

- Purpose: test toughness and durability of prismatic film

- Test Instructions: put the film in the tensile machine, stretching from 90 degrees and 180 degrees.

- Significance of practical application: in areas with strong winds, traffic signs must withstand stretching without tearing or deforming while maintaining their reflective capabilities. Tensile performance testing ensures that the material can withstand these stresses.

Waterproof

- Purpose: test waterproof performance of prismatic reflective sheeting

- Test Instructions: put the film in water, observing whether it seeps water after 24 hours.

- Significance of practical application: If the waterproof property of the micro-prismatic reflective film is poor, moisture can damage the micro-prismatic structure, leading to uneven light reflection and reduced visibility of traffic signs or road markings.

Ink Adhesion

- Purpose: test ink adhesion of prismatic reflective sheeting vinyl

- .Test Instructions: use a grating knife to scrape the ink,then use tape to check whether the ink is scraped off.

- Significance of practical application: This ensures that printed text remains clear in all conditions. If ink adhesion is poor, printed text may fade, peel or blur over time, making signs more difficult to read and potentially compromising safety.

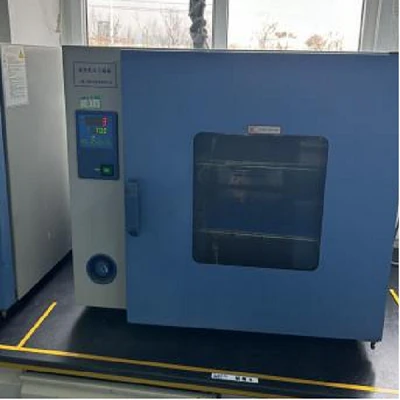

High temperature resistance

- Purpose: test high temperature resistance of prismatic reflective sheeting

- Test Instructions: put reflective sheeting in the oven and observe it after 24 hours.

- Significance of practical application: Traffic signs placed in hot areas, such as deserts or industrial areas, must be durable and reflective in strong sunlight.

Weather resistance

- Purpose: test weather-ability of prismatic reflective sheeting vinyl

- Test Instructions: put reflective sheeting in the nature and observe it after 30 days.

- Significance of practical application: If weather resistance is poor, the film may fade, crack or lose its reflective properties, reducing the effectiveness of the sign and potentially compromising road safety.

How Is the Quality of Microprismatic Reflective Sheeting Tested?Traffic Signs?

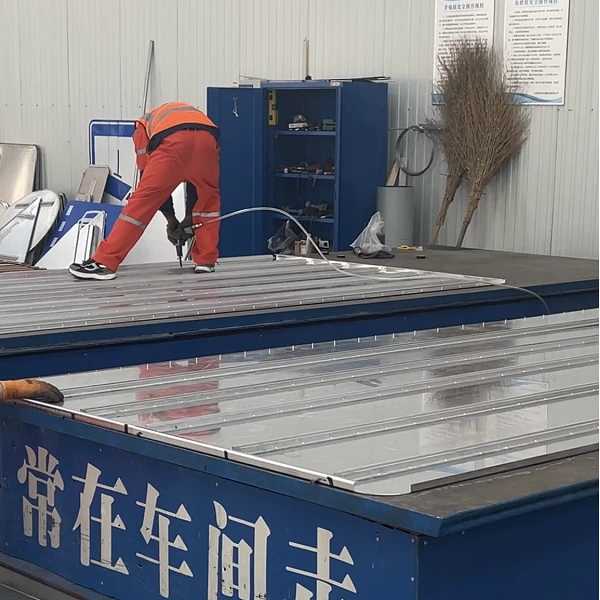

Micro-prismatic reflective sheeting plays a crucial role in enhancing the visibility and safety of traffic signs. This technology ensures that road signs remain highly reflective, even in low-light conditions. But how exactly is prismatic retro-reflective vinyl film applied to traffic signs, and what are the key considerations in its application process?

Plates Selection: High-quality aluminum plates are used as the base to ensure the firmness and durability of the signs, which can resist the damage caused by wind and rain erosion and vehicle collisions. In addition, the aluminum material has lighter weight than steel stainless plate, makes it easy to install underground and less work for the road workers to fix it on the ground. Meanwhile, the aluminum material also has good feature to resist the poor weather the same like steel stainless.

Films Selection:The selection of reflective film is even more important. It must undergo successive tests, covering aspects from reflective intensity and weather – resistance to the firmness of pasting. Every feature is related to the service life of road sign plate, and also related to the driving safety, so the prismatic reflective sheeting factory always tests every sheeting rolls likes XW Reflective. Only reflective fabric material that meet high standards can be applied to sign production.

Cutting:In the production workshop, advanced cutting equipment cuts the base materials into shape according to precise dimensions, with the error controlled within a very small range to ensure the regular shape of each sign.

Printing:The printing process uses professional inks and techniques to ensure bright and lasting colors, and clear and complete patterns. Subsequently, workers carefully attach the selected reflective sheeting and use hot pressing, rolling and other processes to make the reflective sheeting closely connected to the base, eliminating defects such as bubbles and wrinkles to achieve the best reflective effect.

CONTACT US

Please fill out my form, XW Reflective manufacturer will contact you in 24 hours.

PRISMATIC REFLECTIVE SHEETING FAQ GUIDE

Prismatic reflective sheeting is a type of retroreflective material that can be applied to surfaces like pavement or walls to increase visibility in low-light conditions. When light hits prismatic reflective sheeting, it reflects off its surface and back toward the source of light with greater intensity than other types of retroreflective materials such as micro glass beads film.

The material consists of high-intensity tiny prisms that are arranged in rows. It provides high retroreflection, day and night, under wet or dry conditions, when illuminated by vehicle headlamps. When light hits these prisms, it is reflected back at an angle that makes the material easier for drivers to see at night.

The theory behind prismatic reflectivity is simple:

Light travels through the glass at an angle equal to the angle of incidence (the angle at which the light hits the glass). When that light hits the surface of a transparent material such as glass or plastic at an angle greater than 45 degrees (or 60 degrees for acrylic), it reflects off the surface instead of passing through.

In other words, when you have enough light hitting one side of the material (like from headlights), any excess light that reaches the other side will bounce back toward its source rather than continuing on into space as reflected light would do if it were not surrounded by another transparent medium or surface like water or glass, etc.

Prismatic reflective sheeting is a type of retroreflective material that has a prismatic structure. It is made up of two kinds of reflective layers, the base layer, and the prismatic layer. The prismatic layer consists of prisms with different angles and heights. The height of these prisms ranges from 0.5mm to 1mm.

The angle between two adjacent prisms varies from 10 degrees to 120 degrees. This angle determines how much light will be reflected back to its source. The more obtuse the angle, the more light will be reflected back to its source; the smaller the angle, the less light will be reflected back to its source.

The base layer is used as an adhesive agent for attaching the prismatic layer onto a substrate material such as aluminum foil or plastic film. A good bond between these two layers is essential in order for them to work properly together as a reflective material when exposed to light sources such as headlights and flashlights during nighttime driving conditions.

The difference between prismatic reflective vinyl sheeting and micro glass beads reflective film is primarily in how they are made. Prismatic reflective sheeting consists of prisms arranged in rows, while micro glass beads reflective film is made from small pieces of glass beads that form a pattern when viewed from above. Both types of materials can be used to reflect light from headlights back toward the driver’s eyes, giving them more visibility at night when driving on dark roads or highways with no streetlights along the way.

Prismatic reflective sheeting does not require any special maintenance beyond routine cleaning with soap and water or mild detergent. You can use soap and water or mild detergent if you want to clean up any dirt or stains before they get bad enough to damage your new material.

- Good Weather Resistance

- Good Reflective Effect

- Can Be Cut As Any shape

- Long Service Life

- Wide-angle visibility

- Long Distance Visibility (high intensity)

- Multi-Color Possible

Prismatic reflective sheeting is available in different colors like red, yellow, blue, green and white. The color refers to the thickness of the metal coating. Red color has a thickness of about 0.2mm, whereas the white color has a thickness of about 0.12mm.

PVC Prismatic Reflective Sheeting: PVC reflective sheeting is made from PVC plastic which has been dyed red or yellow in order to create an increased contrast against other colors or objects around it. It has been used for traffic signs, warning lights and barricades since the 1970s because it is durable enough to withstand harsh conditions but also flexible enough to be bent into different shapes without losing its shape over time.

Prismatic reflective sheeting is a type of retro-reflective material that can be used in signs and other applications. It is made from multi prisms, which result in a reflective effect.

Prismatic reflective sheeting has many applications including traffic signs, road markings, and clothing for workers on construction sites or other dangerous environments where visibility is important.

Prismatic reflective sheeting is widely used for safety applications such as traffic signs, road signs, bike lane markings and crosswalks because it can be cut into any shape or size without compromising its functionality or durability qualities. Prismatic reflective sheeting can also be applied to hard-to-reach areas using spray-on adhesives or pressure-sensitive adhesives which make this material more versatile than other types of retroreflective materials available on