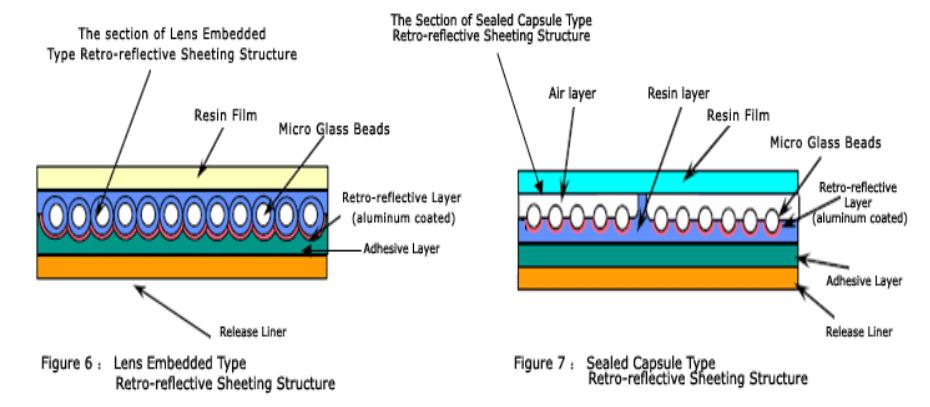

The retroreflective film using glass microspheres (reflective index glass beads) produced with a different technology: direct coating of the microspheres into the surface layer, such as XW7200 engineer grade reflective sheeting; using an air capsule between the surface layer and microspheres as a reflecting element, eg XW1800 high-intensity grade reflective sheeting.

Reflective materials (reflective sheeting and reflective fabric) are widely used in traffic safety and personal safety. To classify the different types of reflective sheeting, it is using the degree of reflection value, also durability, flexibility, impact resistance, etc.

In the production of Engineer grade reflective sheeting, required for 7 years outdoor, always need to apply the front transparent PMMA resin layer, in which glass beaded is immersed uniformly. Then, the PMMA resin layer applied amalgam reflector, then pressure-sensitive adhesive layer and a protective substrate are made of cardboard with a double-sided polyethylene coating.

Leave A Comment