Project Description

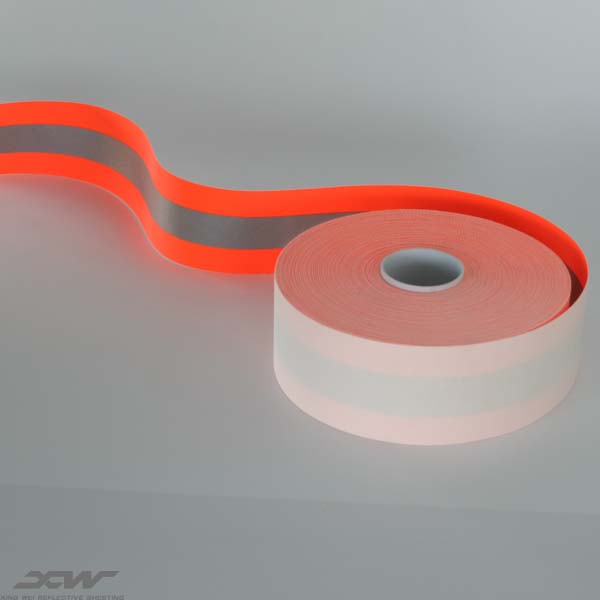

XW10004C Orange Silver Orange Aramid Fireproof Reflective Tape

Reflective Fabric Introduction

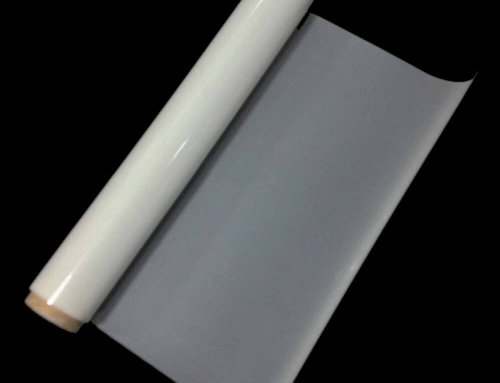

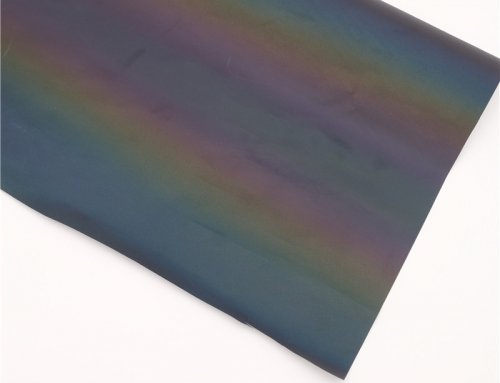

Reflective fabric for clothing is made of substrate, composite glue, reflective layer, and glass beads, widely used for outdoor safety reflective products, such as safety equipment, safety uniforms, work clothing, sanitation clothing. and these reflective safety products’ application benefits from the reflective effect of the reflective fabric tape.

So XW Reflective transfers the microbeads to the cloth base through the aluminized plant film to achieve the reflective effect of reflective fabric tape. Moreover, whether day or night, Reflective fabric always express excellent retroreflective feature, can reflect the direct light from a long distance back to the luminous place.

As we all know, there are kinds of reflective material in the market, the most common reflective fabric materials are reflective chemical fiber cloth and reflective T / C cloth. XW Reflective is one of a leading reflective fabric supplier in China, mainly manufacture and provide glossy reflective clothing, high gloss reflective fabric, reflective hear transfer film, reflective fireproof fabric, reflective tape, reflective glass bead tape, elastic reflective fabric, reflective lattice belt and so on. All of these reflective products have different features & application, with different reflection value and parameters, already passed TUV testing and American ANSI certification, top quality exceeding European (EN471) standards.

XW10004C Fluorescent Orange Fire Proof Reflective Farbic Tape

XW10004C is composed of micro-glass beads bonded to a special polymer with flame resistant durable aramid fabric backing. The fluorescent orange color is improving the visibility during daytime and nightime. It reflects light directly to the original light sourceand enhances the visibility of anyone who wears it. Apply for fireproof reflective clothing, fireman safety vest.

The reflective coefficient (R, in cd/lux/m ) of XW10004C can meet the requirements in international standards like EN ISO 20471, ANSI/ISEA 107, CSA-Z96- 15, AS/NZS 1906.

Technical Data

- Attachment type: Sew On

- Daytime color: Fluroscent orange / Silver / Fluorescent orange fire proof reflective fabric

- Backing fabric: 100% Aramid

- Reflectivity: R>420 CD/LUX typical reflectivity, 330 CD/LUX mimum reflectivity

- Home wash cycles: 50 cycles for home wash and dry cleaning

- Width: up to140 CM, can be customized

- Certification: EN ISO 20471, ANSI/ISEA 107, CSA-Z96-15, AS/NZS 1906.

Leading Time of Fire Proof Reflective Fabric

- We have regular stock of reflective fabric products for sale in the warehouse, if not, it will take 7-10 days to arrange reflective fabric production & shipment after deposits receive. Thus, please confirm with XW Reflective maufacturer before ordering our reflective tape material.

OEM & ODM Available

- Customized reflective fabric width available( Can’t over the Maximum width).

- Customized reflective tape fabric package mark service.

- For any client’s who want printing LOGO on retro refelctive fabric, please contact with our staff and it request a high quantity

Quality Control for Reflective Fabric

-

Raw reflective material inspection

XW Reflective has a strict quality control for reflective fabric material production, from face film to release paper, all the maufcturing material of reflective taple vinyl will be strictly inspected before putting into production.

XW Reflective always check reflective manufacturing materials, and must ensure these raw reflective fabric is in line with standard of reflective stickers production, then take away the disqualified raw reflective material, finally, XW Reflective will arrange reflective sheets manufacturing by the leftover reflective initial material.

-

Reflective material check during production

QC department will cut reflective production samples, bring it to our own lab then inspect brightness, stretch, thickness, etc.,also they will bring Brightness detector to production line and check for brightness.

XW Reflective arrange 3 technical staff to inspect reflective fabric tape manufacturing in every reflective material production line, they can take measures quickly and adjust reflective sheets production once reflective pinstripe tape production occurs some quality problem, in addition, they will paste poor quality signs on these problem reflective products, deliver them to QC lab for a quality analysis.

-

Final inspection of reflective fabrics

When Rolling the final product, workers will check and remove the poor quality sheeting and mark the joint. Each joint we arrange extra reflective sheeting for clients. If the joints out of allowable range, we label the roll as B grade.

We will sample test the final product, and also do inspection under client’s requested.

After Sales

XW Reflective try our best to reduce the quality problem for our reflective glow in the dark heat transfer vinyl, but if you still find quality problem in our heat reflective fabric, please don’t hesitate to contact us for best after sale service, and XW Reflective will provide best after service until you are satisfied with our service.

If you find your product has poor quality reflective fabric – whatever how many they are. Take a picture or video for it, show us, and our team will reply within 24 hours.

Package of Fire Resistant Reflective Tape

- Inner packing: ( Plastic seal )+ Plastic bag

- Outer packing: Export carton box

- *Please contact our staff for customized products.

- *The data does not include the pallet size, we recommended increasing the pallet to protect the goods.

- Loading Port:Ningbo/Shanghai or other China port

Care and Maintenance

- Actual life of reflective pattern printing fabric depends on cleaning method and wear conditions.

- Do not presoak, Machine wash warm 40℃ ( 105℉ ). You may use a mild detergent, but No Bleach or Fabric Softener!

- Try to avoid wash the reflective products with your work jeans or any clothing with rough fabric or edges. The microscopic glass beads on the reflective fabric can be worn off by rough texture.

- Try to line dry your reflective products. If you choose to machine dry, try to remove the product immediately. The added heat can damage the reflective fabric.

- Most of our reflective fabric contains aluminum layer, and sweat /oil/ water stains may occur if the surface of the product has direct contact with hands during application and is then exposed to hot and humid conditions. Even though these blemishes won’t affect performance of the product, we strongly recommend handling the reflective fabric with gloves and keeping them in the environment of below 26.7 °C (80 °F) and lowering than 70% relative humidity

Resources

- FAQ

- Reflective material download

- Certificate

Related product

| Model | Fabric backing | Reflectivity | Reflective side | Home Wash cycles | Standard

( EN20471, ANSI107 ) |

Width | Color |

| XW10002B | Cotton | R>420 | Single | >50 | √ | Up to 140cm, customized | Silver |

| XW10002C | Cotton | R>420 | Single | >50 | √ | Up to 135cm, customized | Orange-Sliver-Orange |

| XW10002D | Cotton | R>10 | Single | NA | Up to 140cm, customized | Fluorescent Yellow | |

| XW10004A | Aramid | R>420 | Single | >50 | √ | Up to 135cm, customized | Silver |